Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

UK based

KASTENLOK INDEX

-

HOME

-

PRODUCTS

-

DIGITAL

-

PROJECTS

-

Dioramas!

-

Free DCC Sound files

-

Bachmann Baldwin 009 invisible stayalive

-

Bachmann Quarry Hunslet

-

Bachmann Mainline Hunslet

-

Diesel Inspection car

-

Heljan Manning Wardle problems

-

Kato Class 800 upgrades

-

Kato Take-a-part

-

Minitrains Decauville

-

Minitrains Tramway

-

Liliput H0e coach interior

-

Pacer 009

-

Tillig T1

-

-

TIPS

-

NEWS

-

ORDER

-

MORE

-

SERVICE

-

HOME

-

PRODUCTS

-

DIGITAL

-

PROJECTS

-

Dioramas!

-

Free DCC Sound files

-

Bachmann Baldwin 009 invisible stayalive

-

Bachmann Quarry Hunslet

-

Bachmann Mainline Hunslet

-

Diesel Inspection car

-

Heljan Manning Wardle problems

-

Kato Class 800 upgrades

-

Kato Take-a-part

-

Minitrains Decauville

-

Minitrains Tramway

-

Liliput H0e coach interior

-

Pacer 009

-

Tillig T1

-

-

TIPS

-

NEWS

-

ORDER

-

MORE

-

SERVICE

-

HOME

-

PRODUCTS

-

DIGITAL

-

PROJECTS

-

Dioramas!

-

Free DCC Sound files

-

Bachmann Baldwin 009

-

Bachmann Quarry Hunslet

-

Bachmann Mainline Hunslet

-

Diesel Inspection car

-

Heljan Baldwin 009

-

Heljan Manning Wardle problems

-

Kato Class 800 upgrades

-

Kato Take-a-part

-

Minitrains Decauville

-

Minitrains Tramway

-

Liliput H0e coach interior

-

Pacer 009

-

Tillig T1

-

-

TIPS

-

NEWS

-

ORDER

-

MORE

-

SERVICE

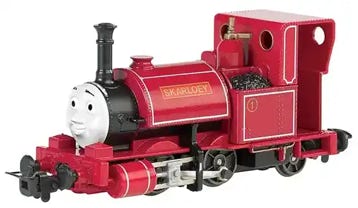

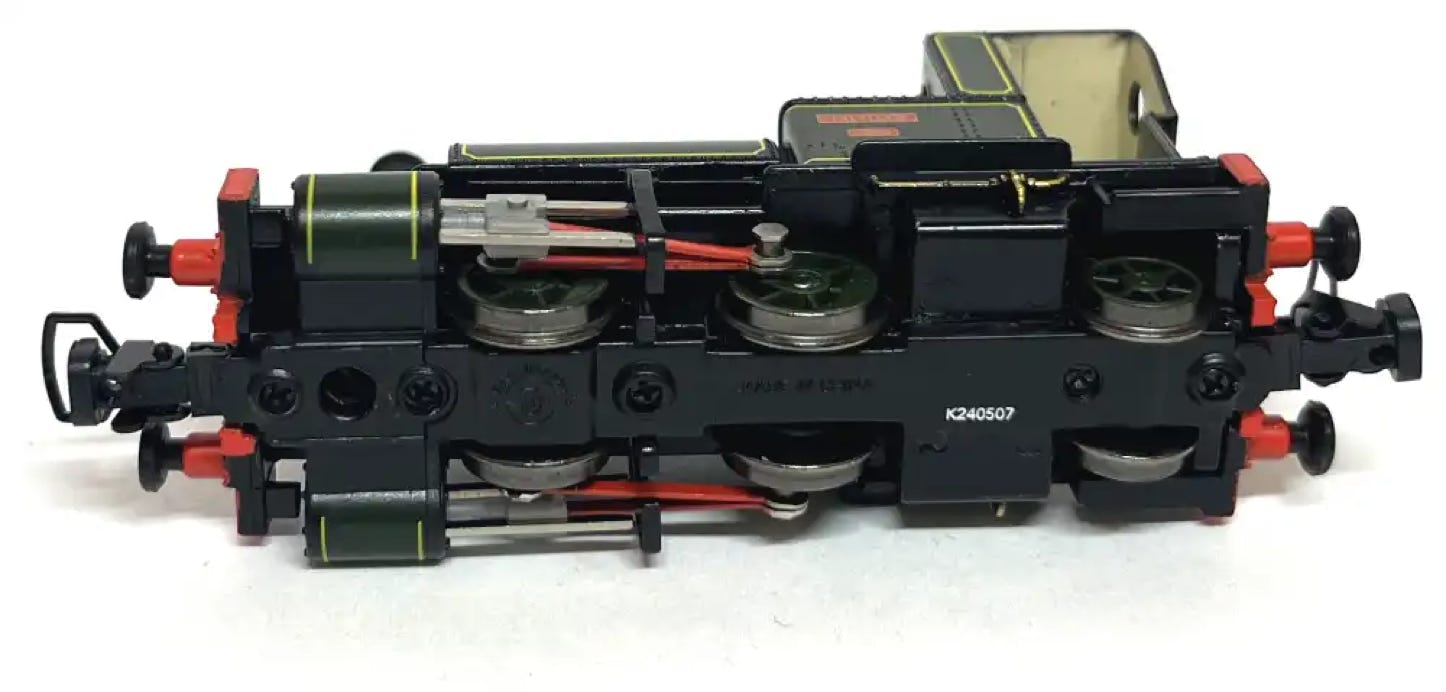

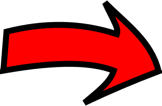

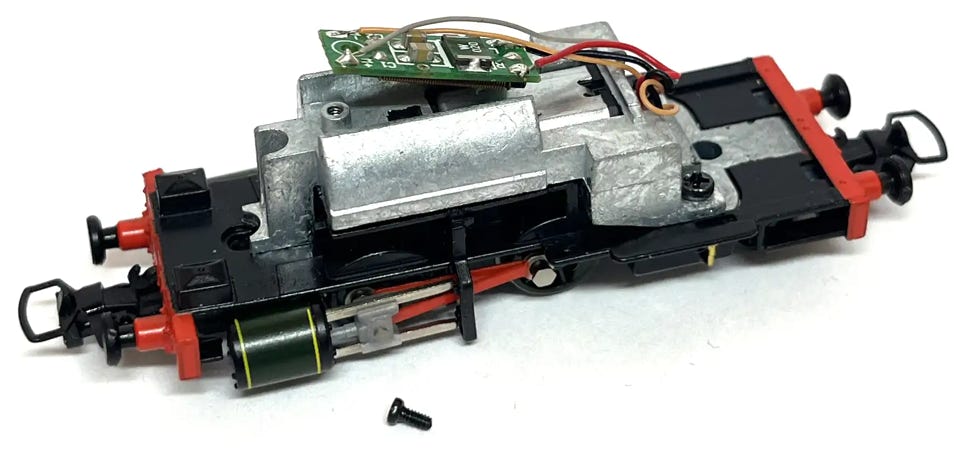

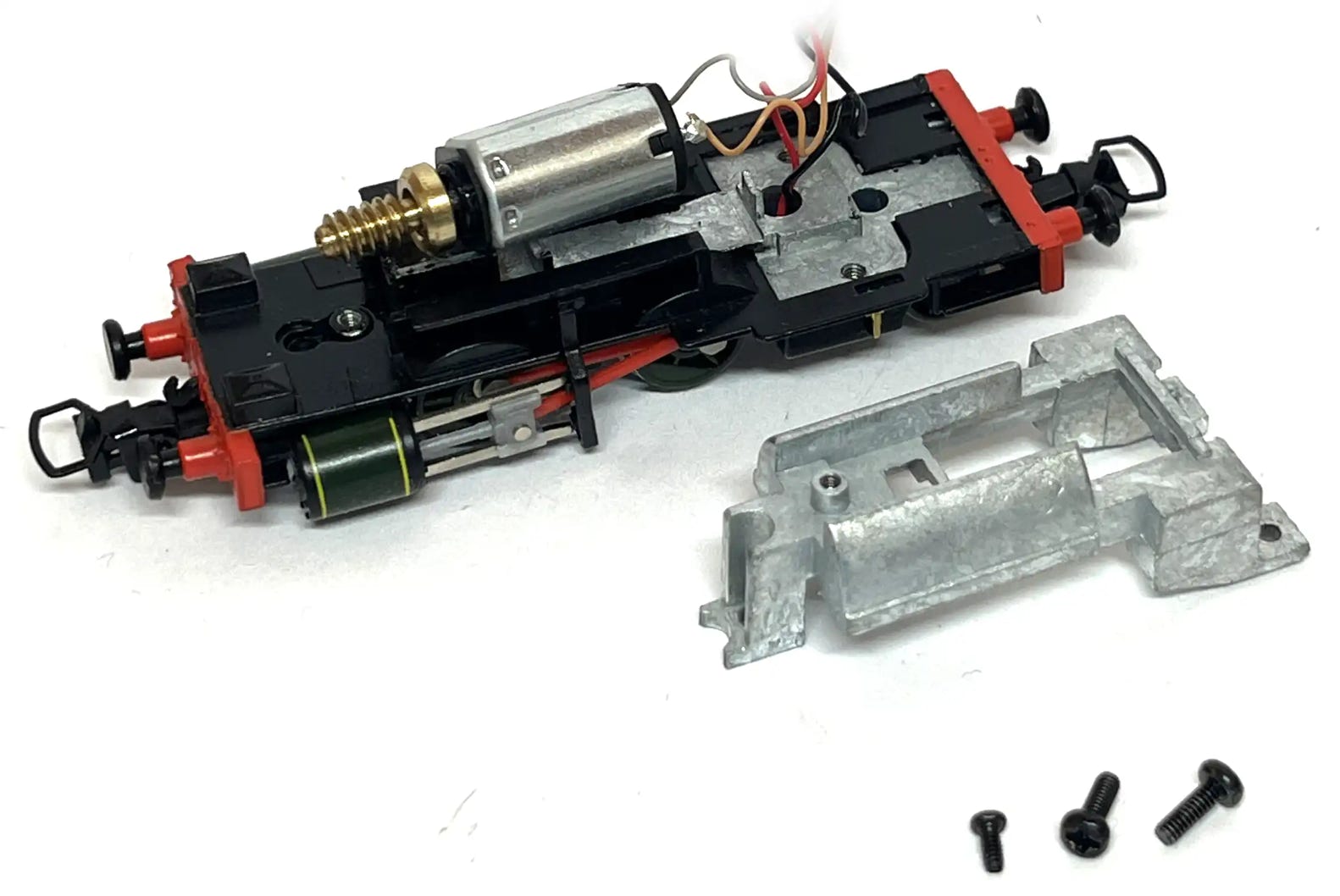

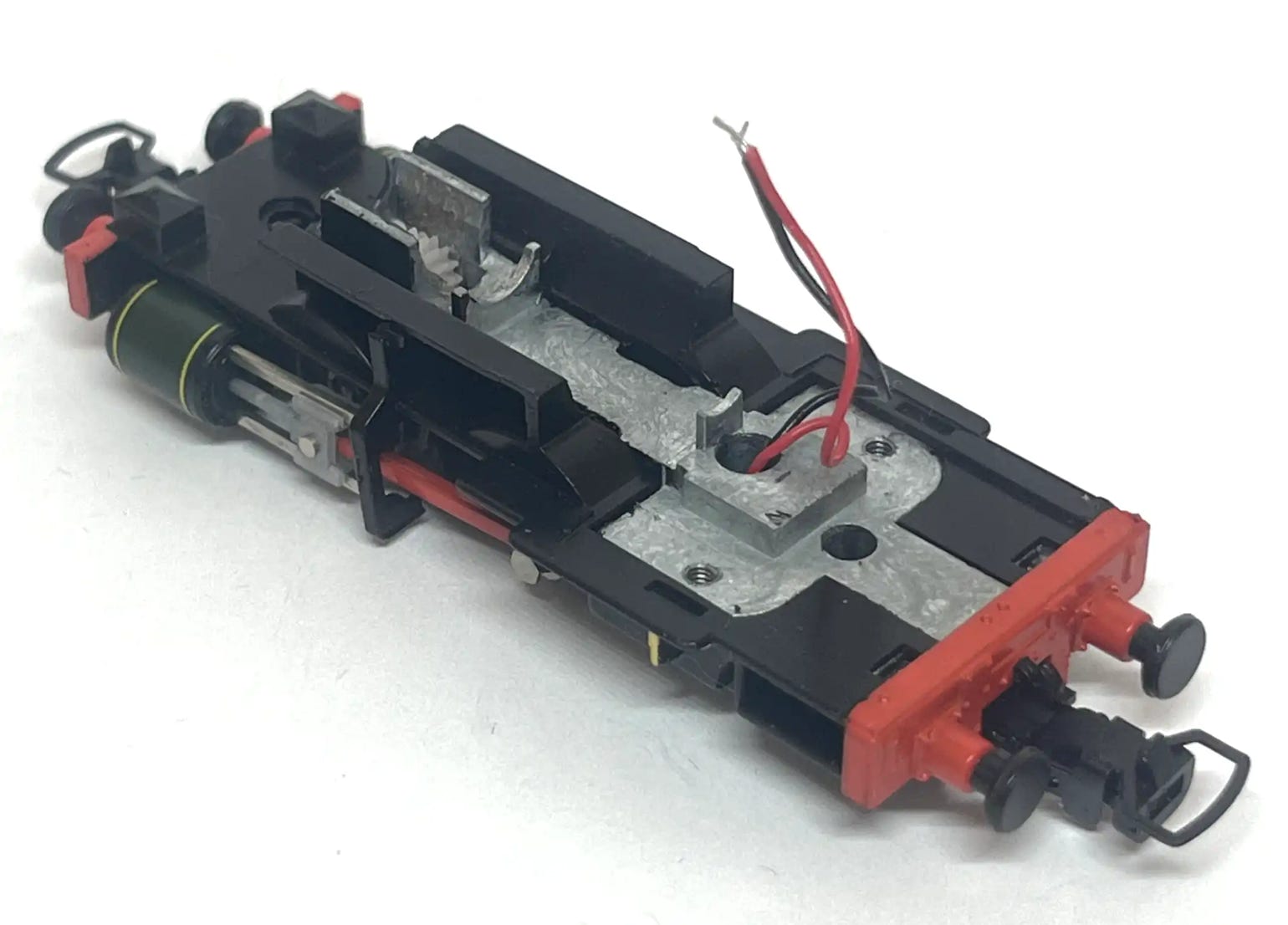

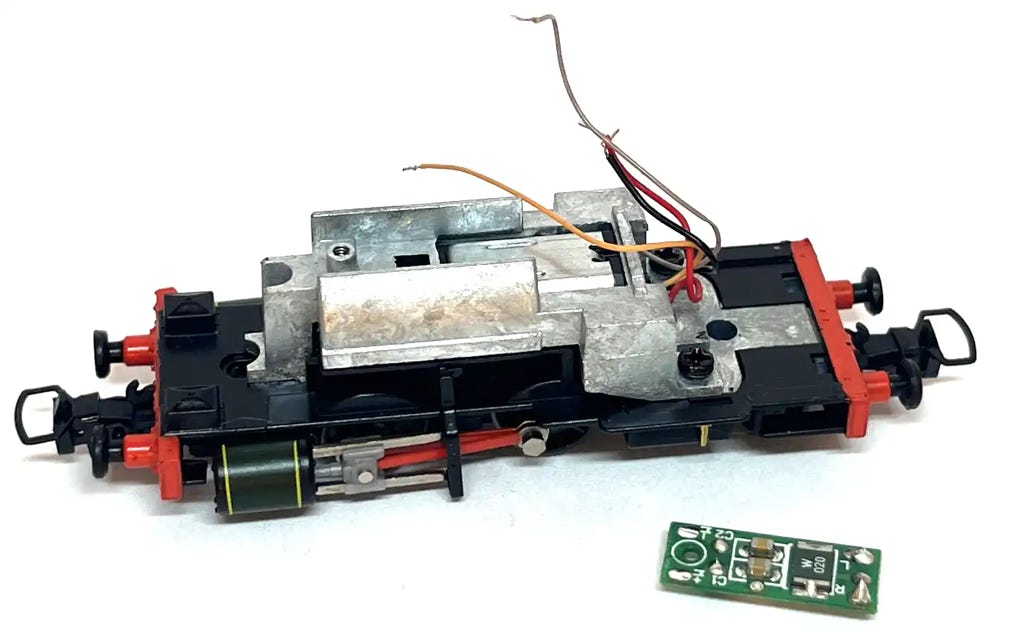

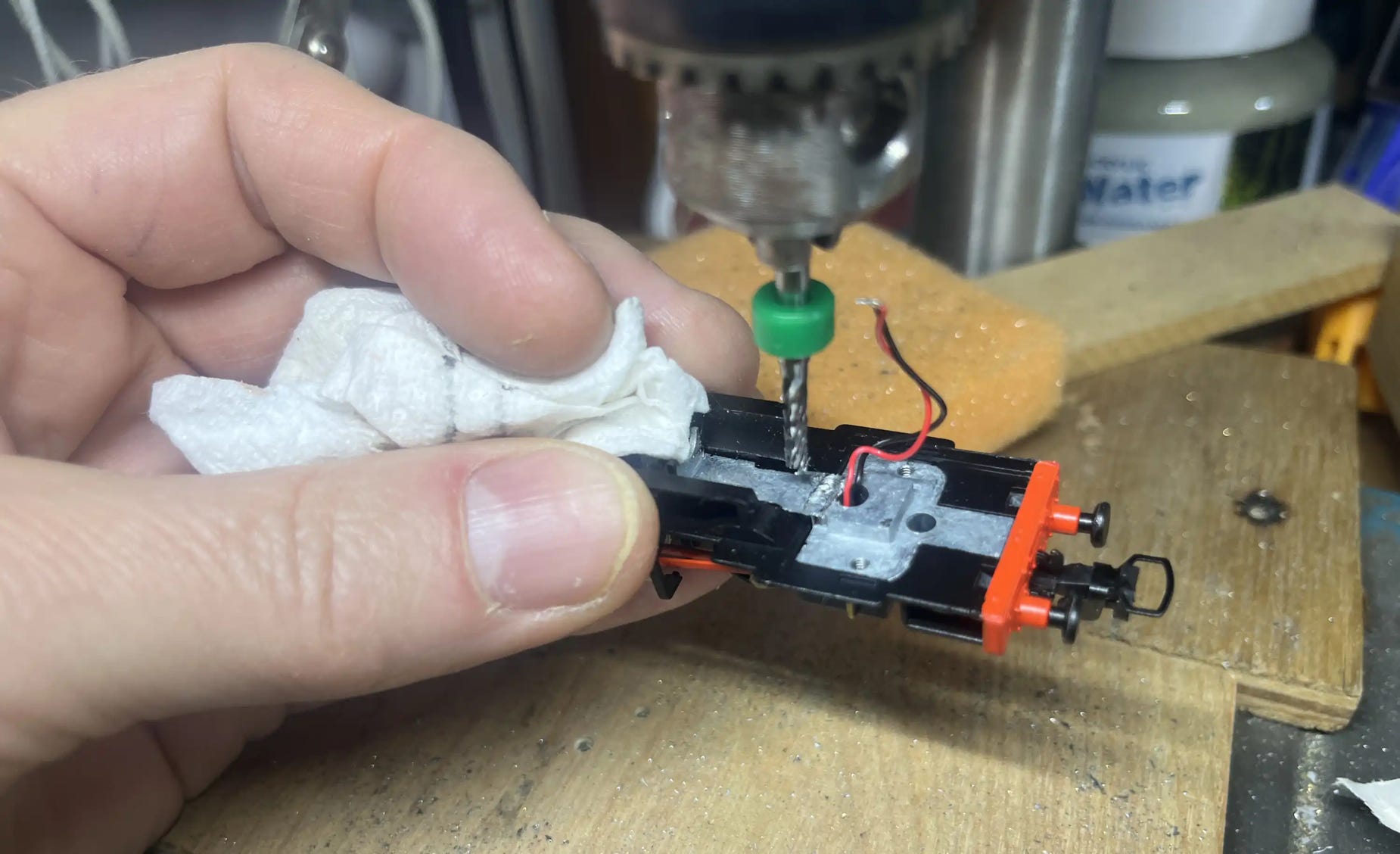

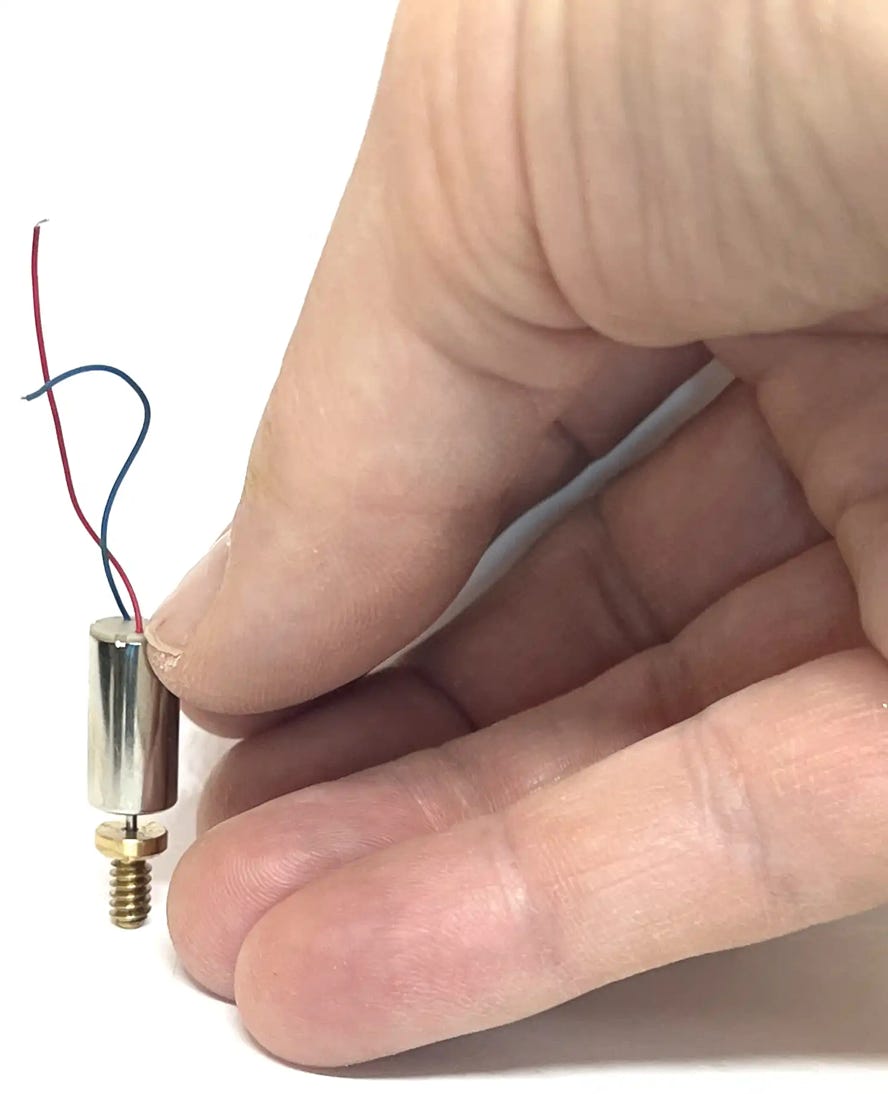

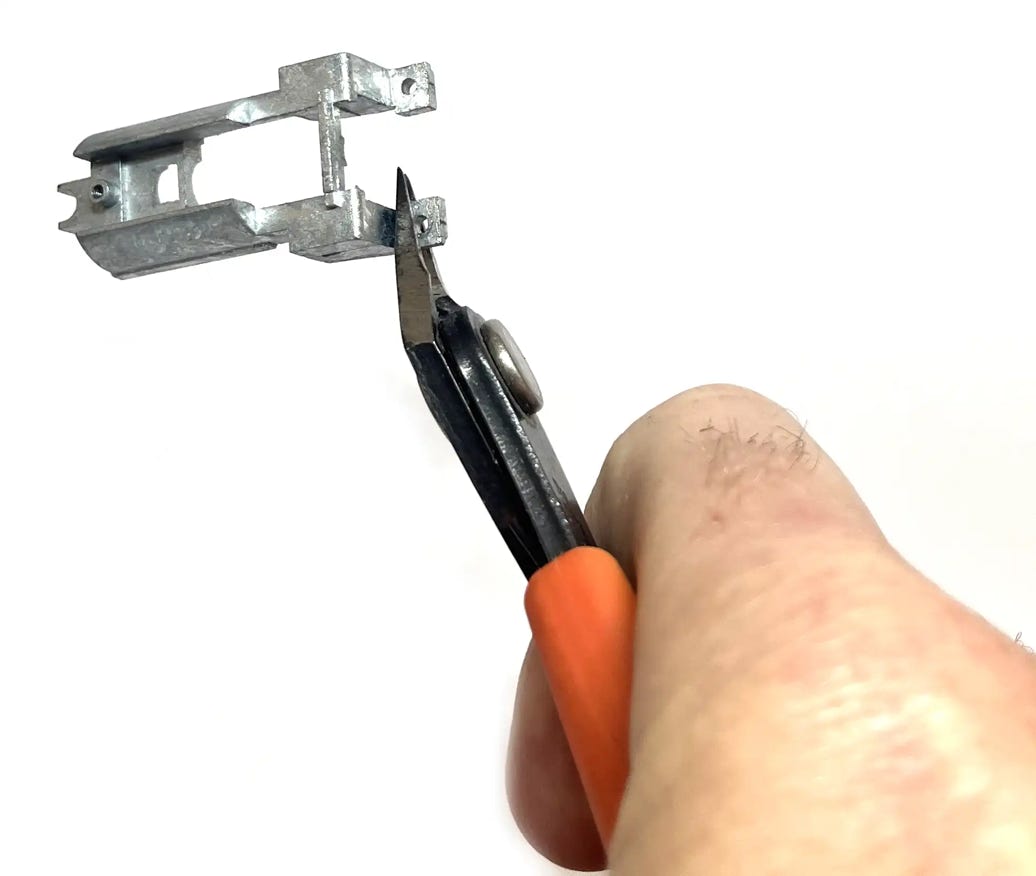

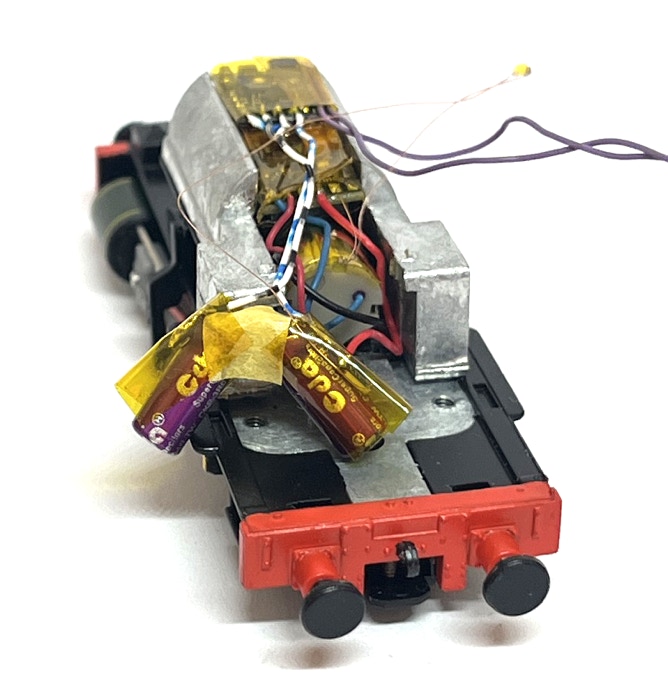

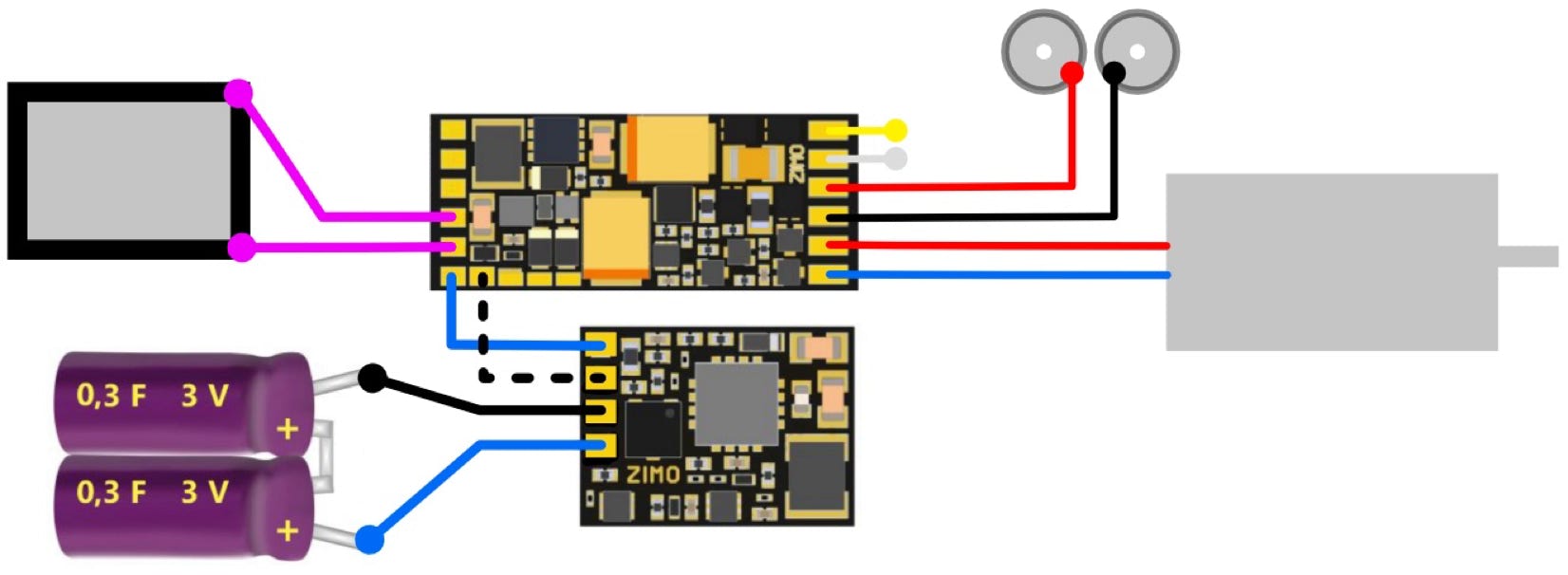

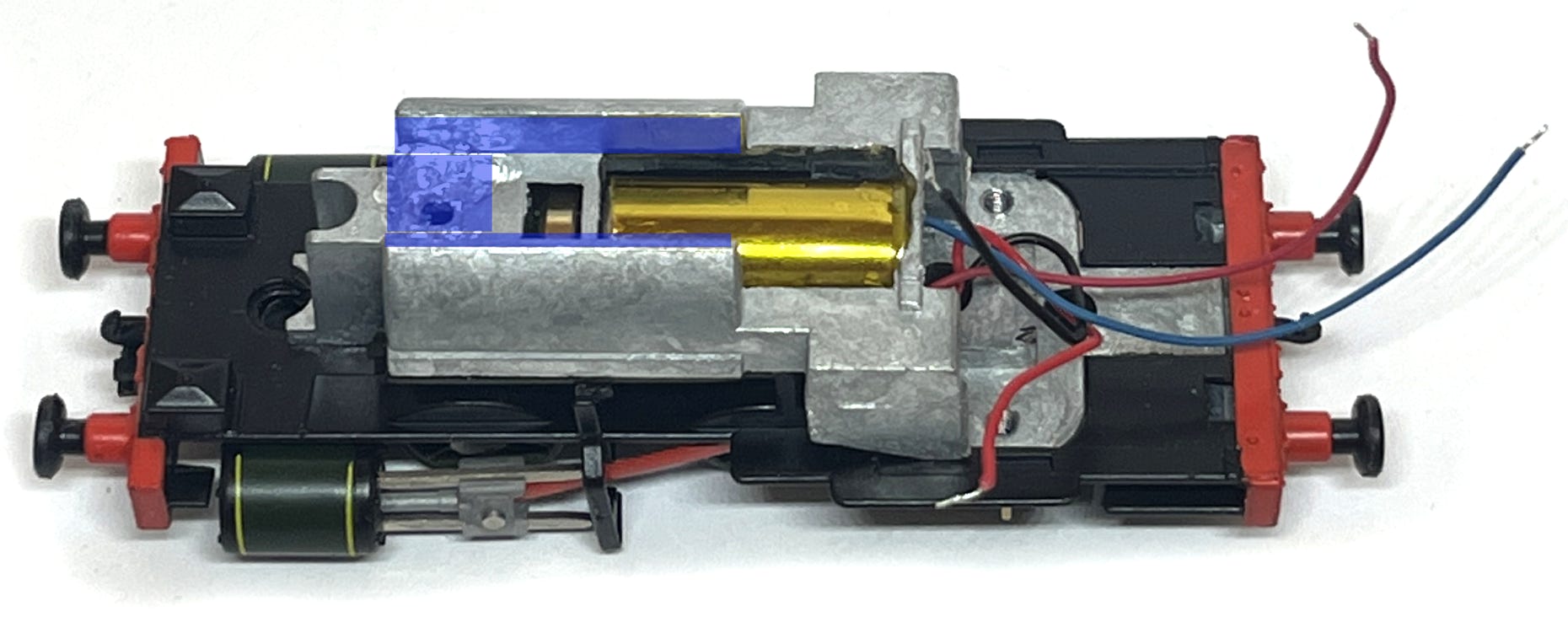

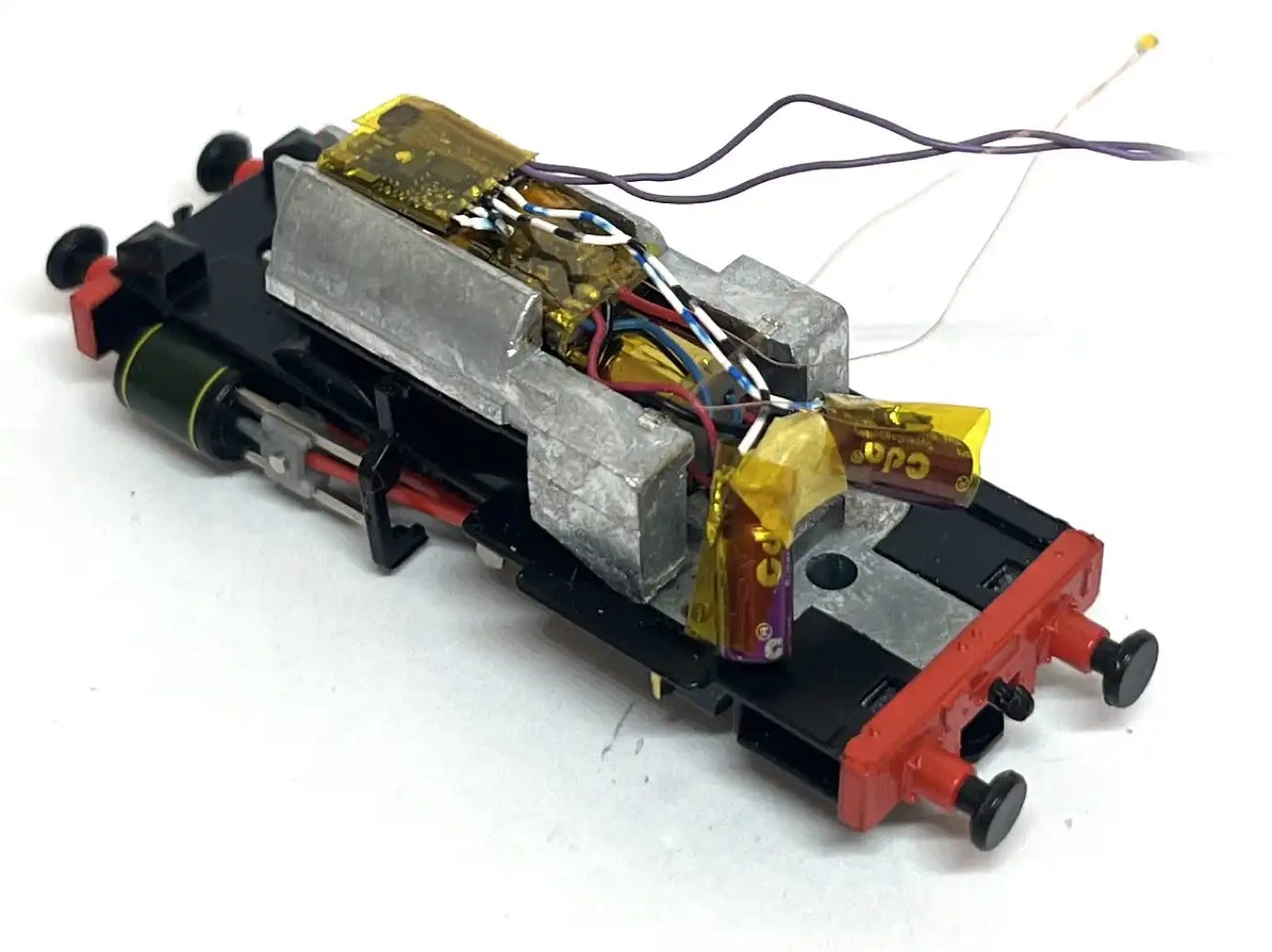

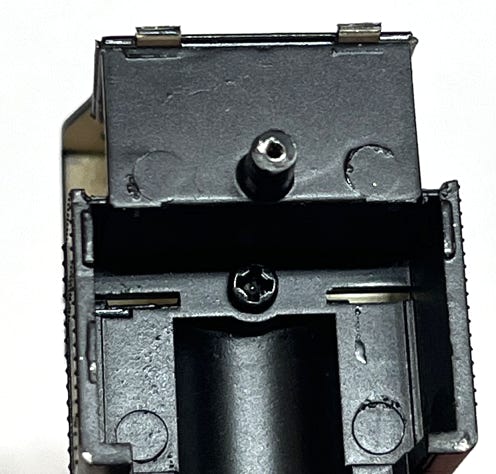

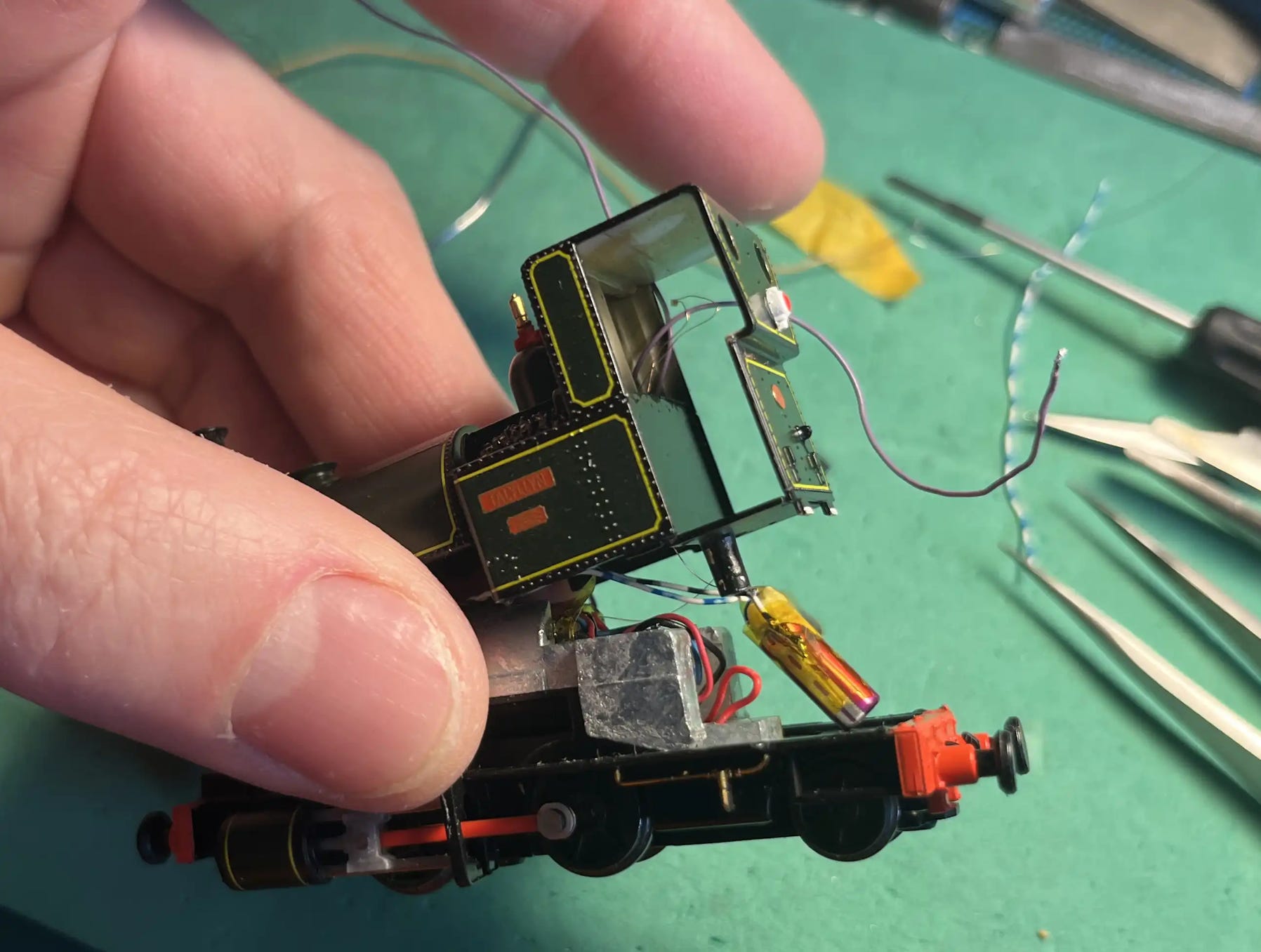

A guide to installing decoder and sound

Bachmann Talyllyn/Skarloey