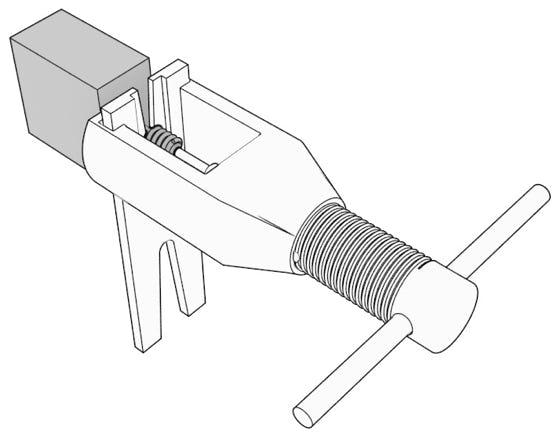

To remove a worm, gear or flywheel (I will use worm to refer to all from now on) from a motor, can me a skill on its own. A plastic worm can (most of the time) easily be pulled of with your fingers. A brass worm, which is either glued or has a press fit on a shaft, can be a more challenging case. A Gear puller, such as being sold here in the Tramfabriek webshop, can be a great help.

Option 1: Gear puller

A Gear Puller (download instructions on how to use it here) presses a pin inside the worm/gear on the shaft, so the pin will be pushed out of the worm/gear. This will work in many instances and is the easiest way to remove a worm/gear, but it doesn’t always work. Sometimes the glue is stronger than the pin. Especially when you’re using the smallest, one millimeter pin, as spare parts are not available.

DO NOT KEEP ON TURNING when you notice that it won’t give. In a case like this, you could try to release it by heating it up with a torch (brass worm/gear only, not plastic of course!!). But be very careful, a brass worm will be soft, so keep it as low as possible in the plate (the plate with the two V gaps) to prevent that one of the ends of a worm will be misshaped.

With my lathe, I made a simple “breaker” out of brass. It’s a small adapter that slides on one of the pins of the gear puller. On the top is a small stub to use to break the glue in the shaft of the worm. To push the rest out, I can then use the normal pin that comes with the gear puller. But I can understand not everyone has the tools to make it.

Detailed info about the gear puller on the GEAR PULLER PRODUCT PAGE. There you can also purchase extra pins.

Option 2: Hammer it out (especially useful for Minitrix models)

Every model train mechanic knows, worms & gears should not come close to a hammer. For some worms however, this is the best approach. Like Minitrix models, where the gear puller will only destroy its pin. For a worm with a shaft, as pictured on the right, there is not much risk in damaging the worm, as it is the shaft of the worm which takes the impact. I use the plate that comes with the gear puller under the worm to support it.

You might have to resort to this method with a worm without a shaft, but beware! The risk is you damaged the outer blades of the worm. In this case, I would advise to protect it with some tough foam or rubber at the bottom (piece of bicycle inner tyre tube for example) and move it as far in the “V” groove of the plate that comes with the gear puller..

1

2

3

Find a nail with the right size, or better: a steel axle from model train wheels. They come in 2, 1.5 and 1 mm sizes and when you put them in a pillar drill, they only need to be filed a little bit to get to the right size to push the shaft out of the worm. Steel axles are much stronger than a nail. To make it even a better tool, I drilled a hole in a round piece of 10 mm diameter wood, made a hole just a bit larger than the diameter of the pin and pressed the axle in it. A piece of hard plastic or even better, brass, does the job as well.

Using a Proxxon or torch you use in the kitchen, heat up the worm for about 5 seconds. In this case, the bottom tube part, as the axle will only be stuck about 5 mm into this part. Heating the brass will soften the brass enough to get it out pretty easily. If you don’t heat the brass, you probably will bend the pin.

Then quickly, but carefully, hammer the motor shaft out of the worm. A few hits will do it. If it doesn’t work the first five hits, heat the brass up again and hammer again.

Option 3: the Screw driver

Sometimes, when a flywheel is fitted too tightly, you might want to use the plate of the gear puller kit and one or two screw drivers to wiggle it off. It could also be done with a worm, but keep the slotted plate of the gear puller set between worm and screw drivers, to protect the blades at the end of the worm.

If you have any other valuable tips, you’ re more than welcome to share them with me.

•