UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

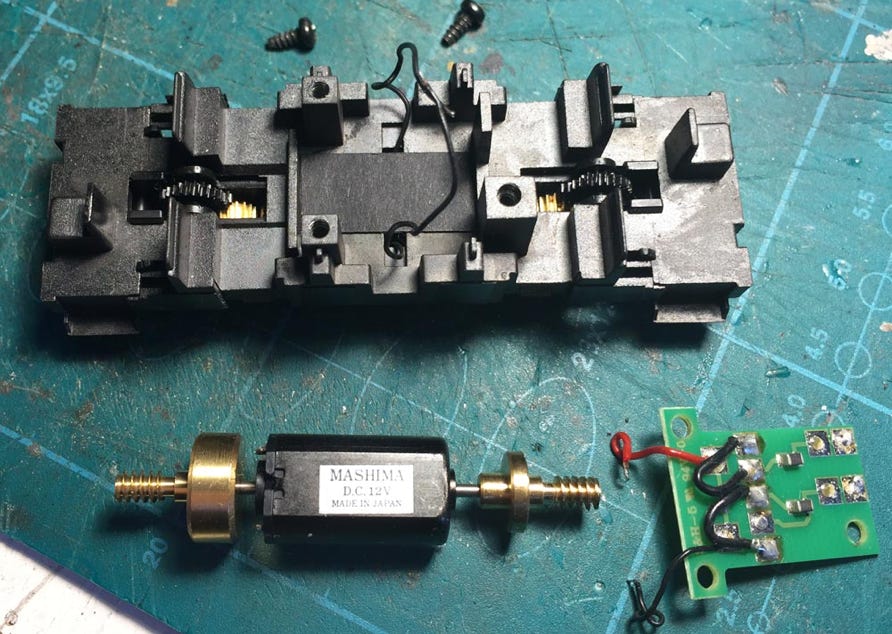

Fits Bemo with flywheel with wheelbase 40.2 or 51.2 mm, Art 1009, 1209, 1609. For H0e/H0m and H0 models. This is the latest, revised version.

To select and purchase the right upgrade kit for the right Bemo railbus, go to this page.

Art. BEWISM-C

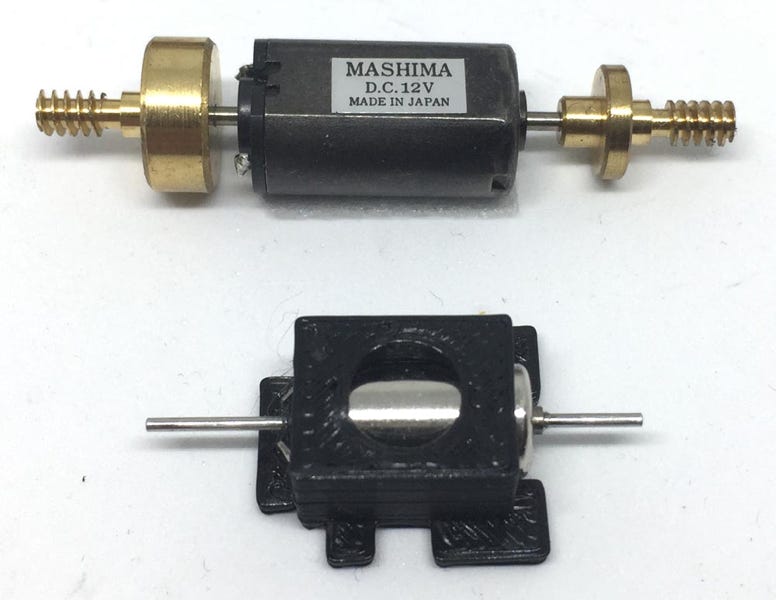

Contents of the kit:

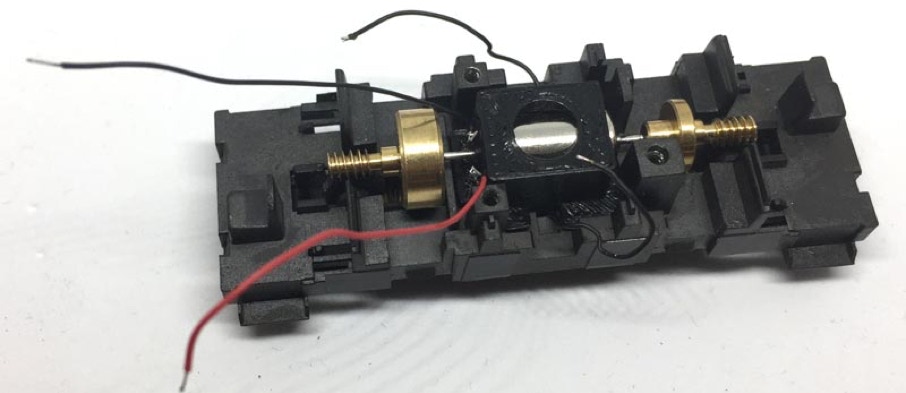

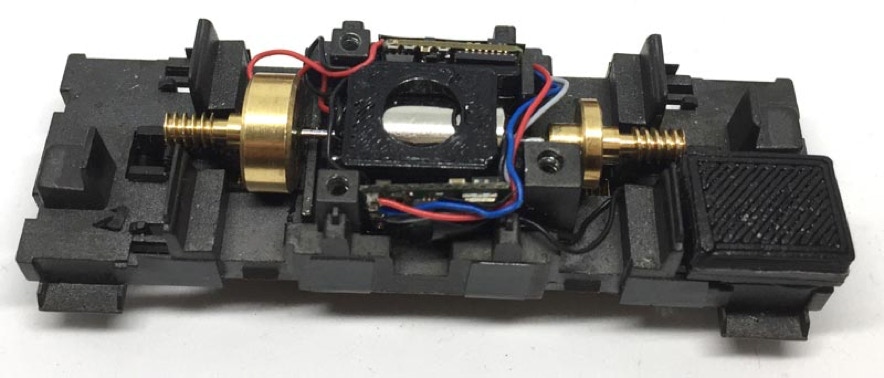

1x 8x16 mm motor with two shafts

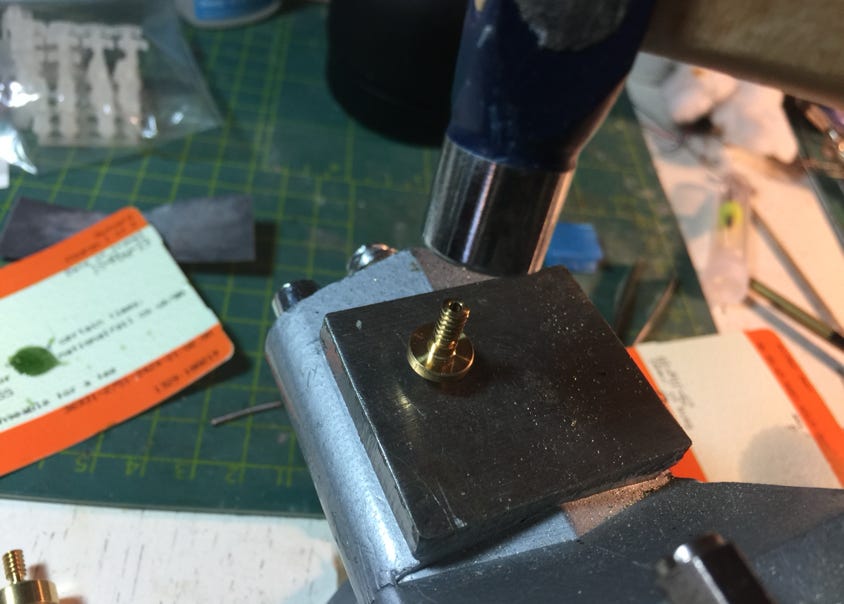

1x motor casing

2x brass adapters for worm/flywheel

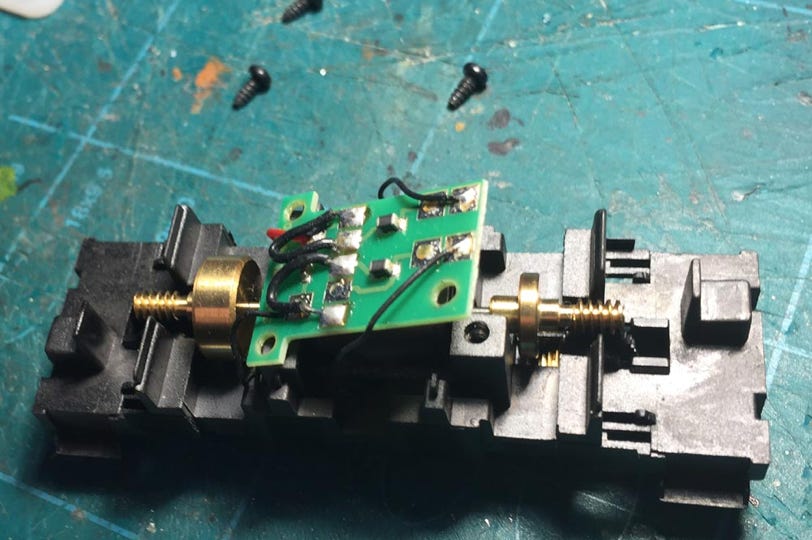

Conversion Bemo Wismar Railbus V3 (latest version with flywheel) to 12V coreless motor