UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

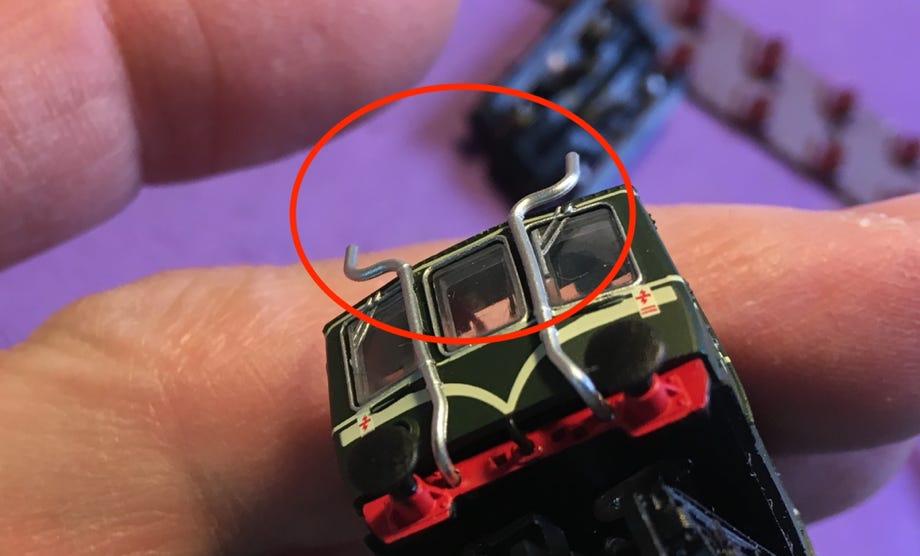

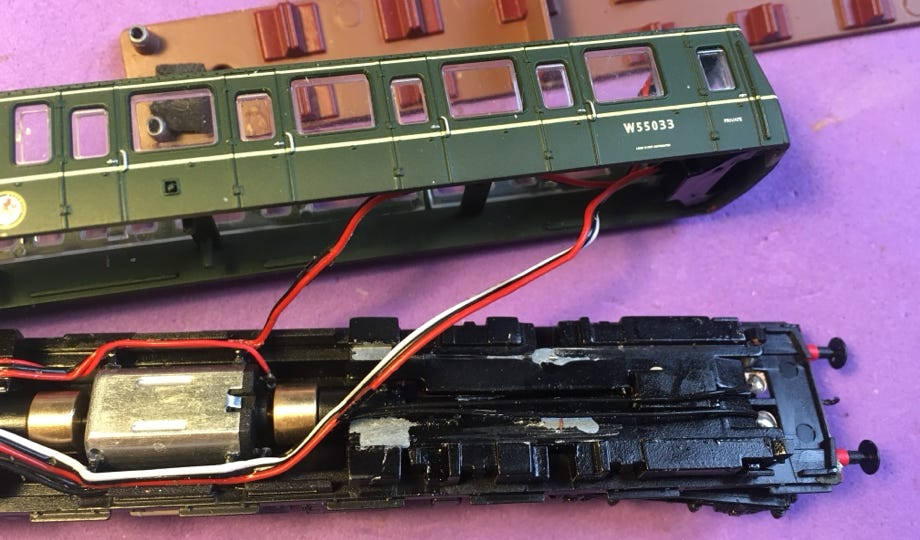

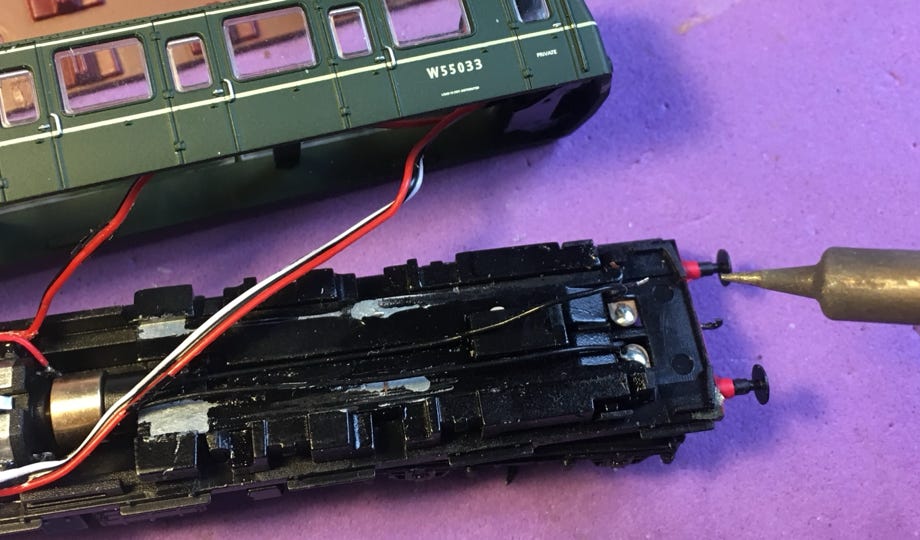

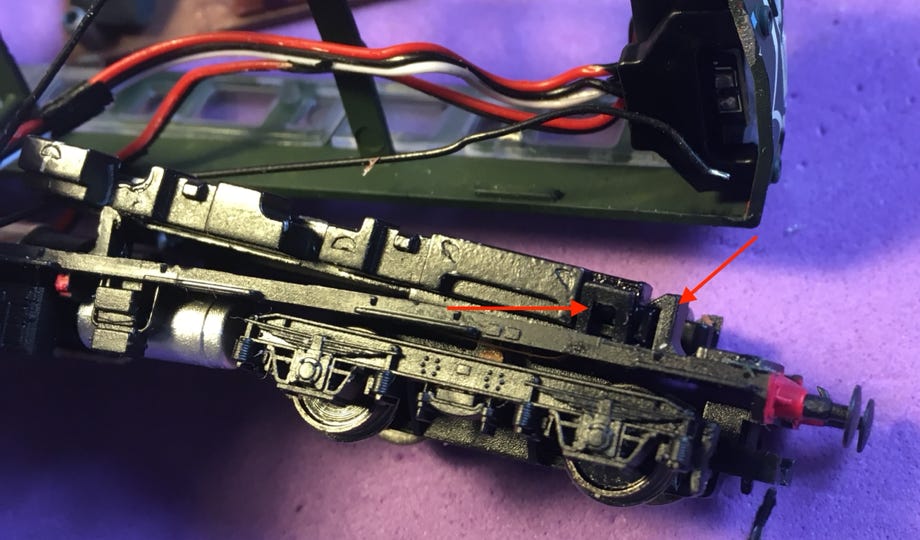

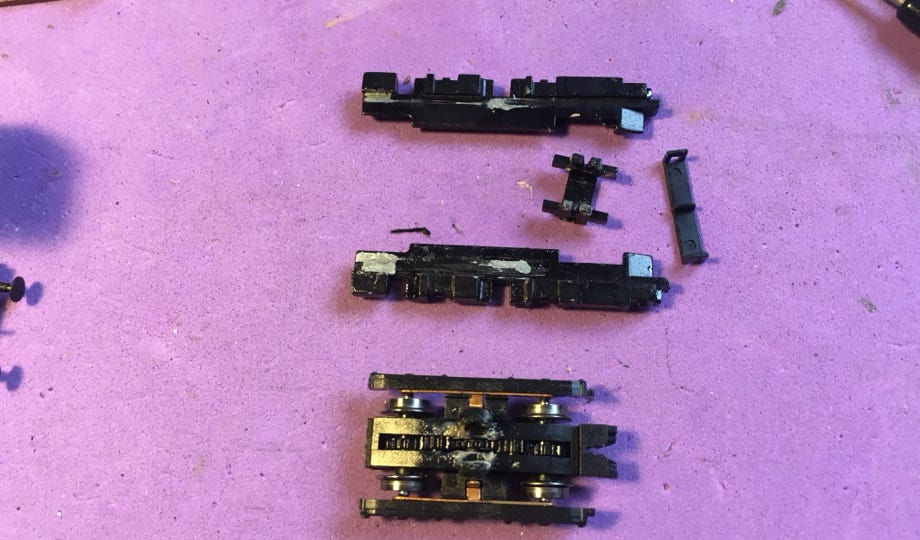

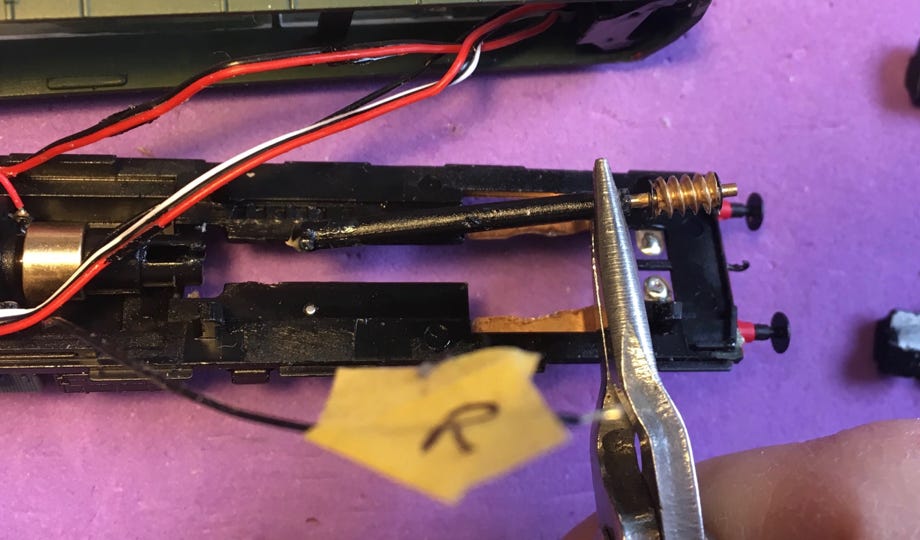

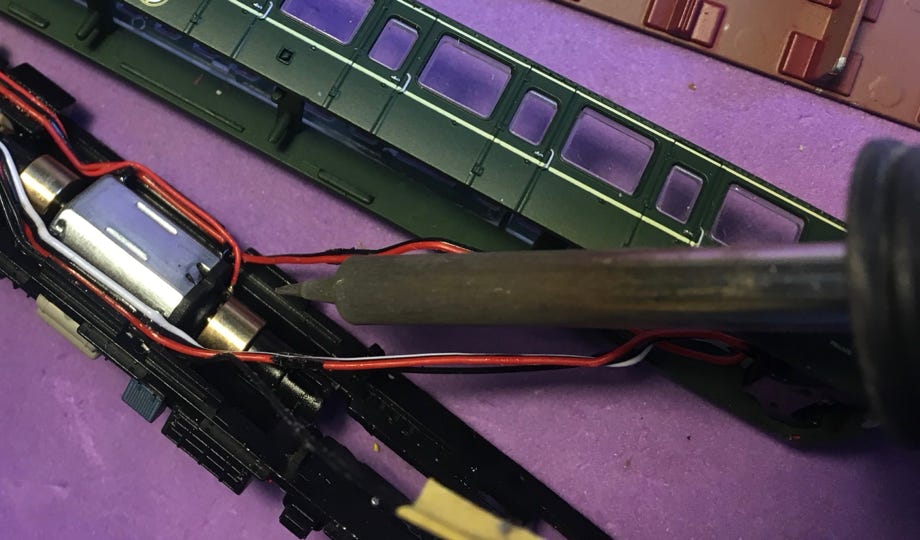

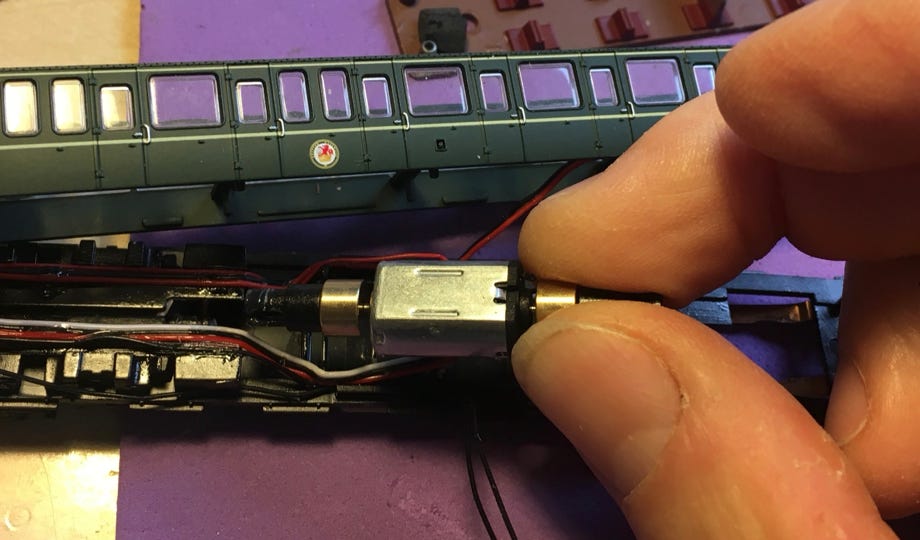

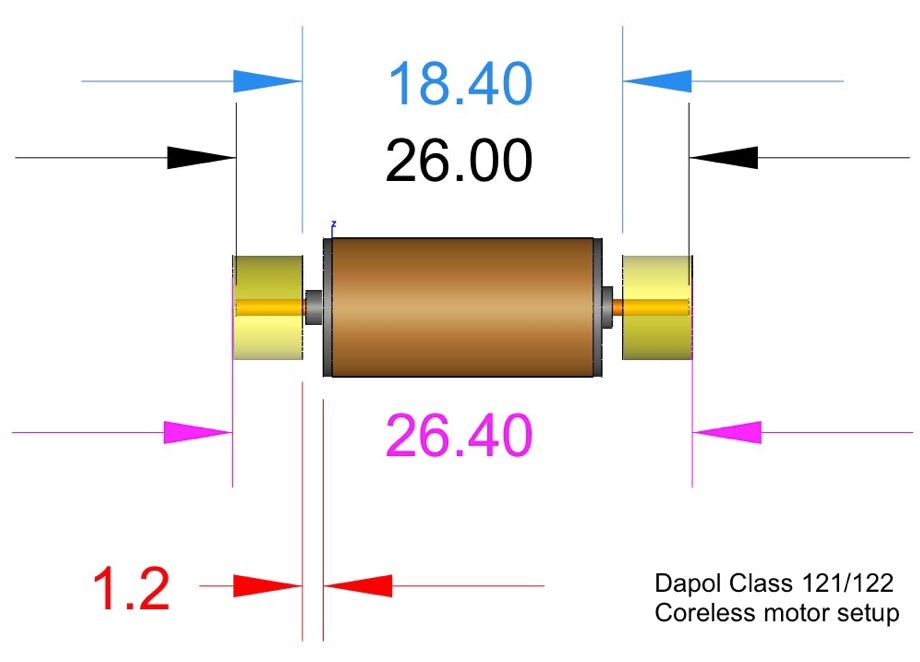

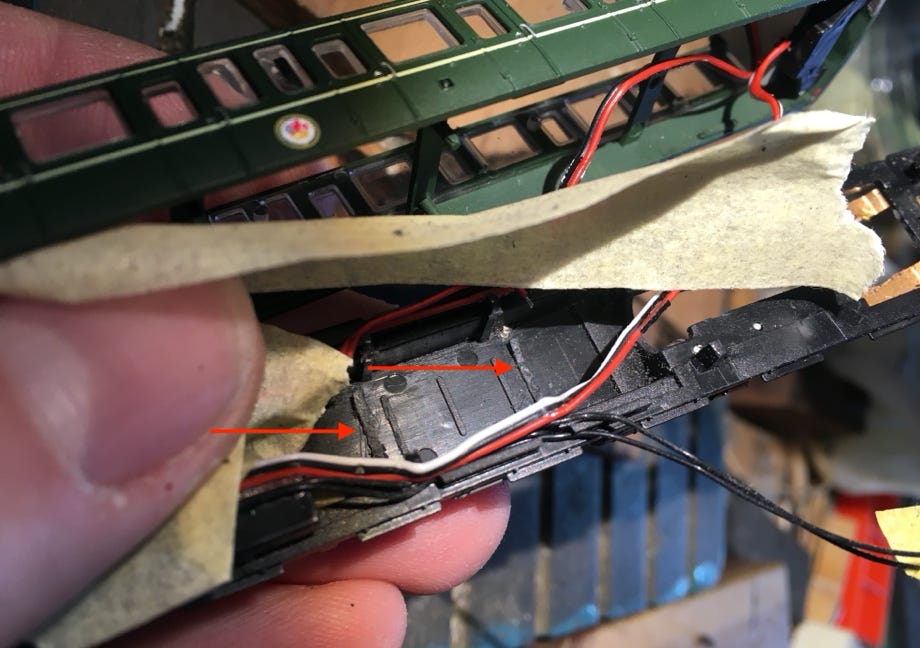

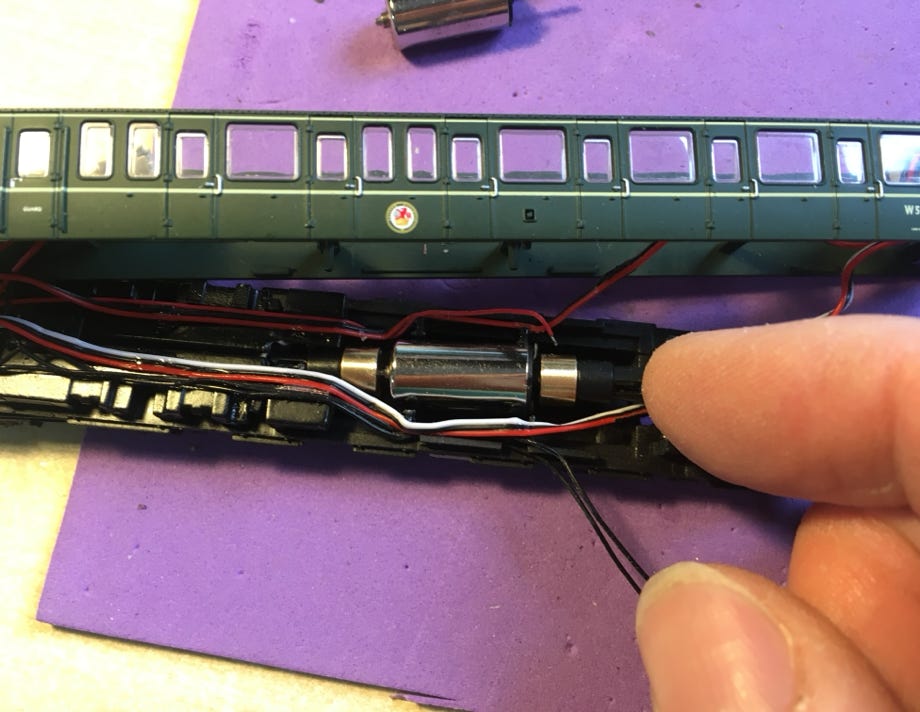

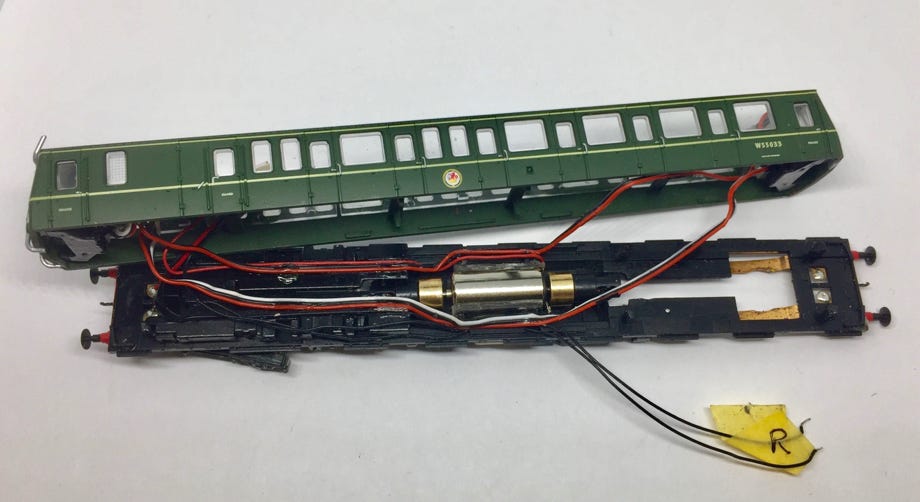

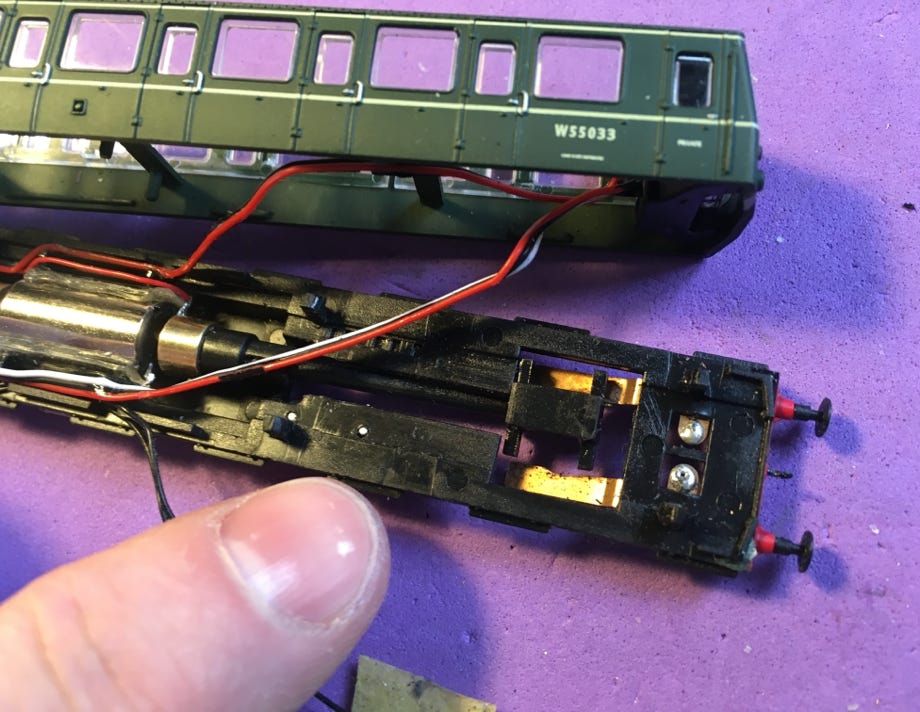

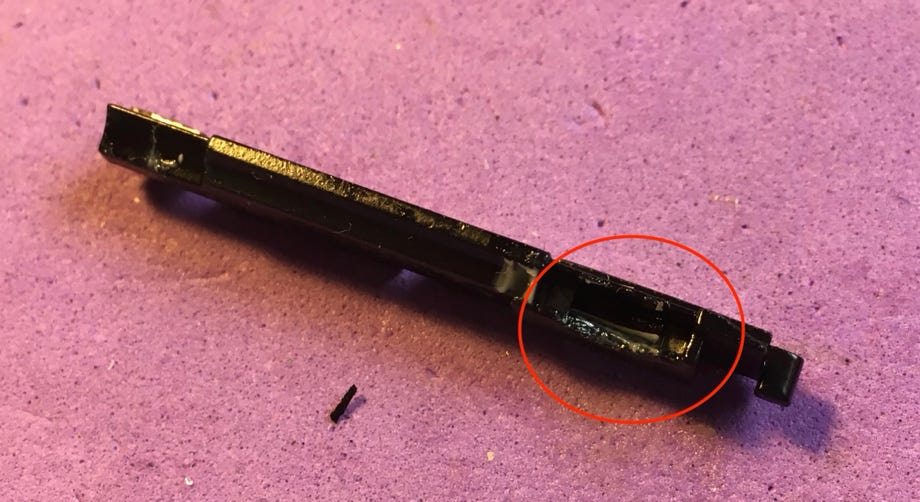

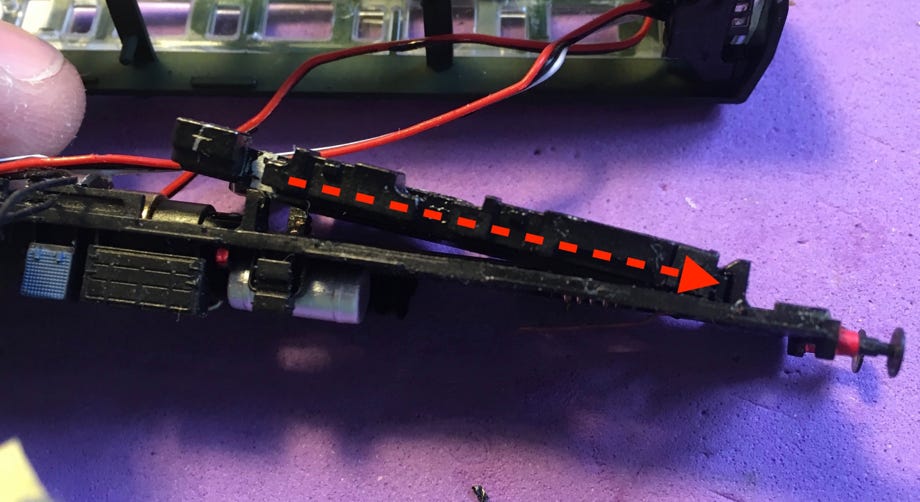

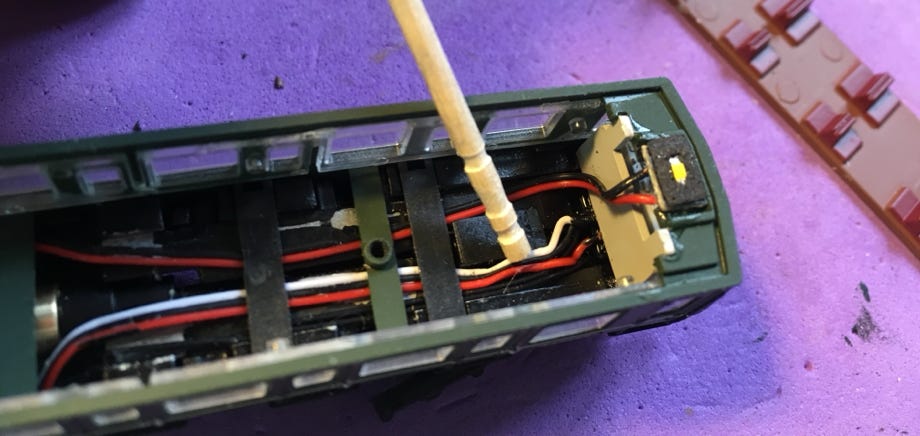

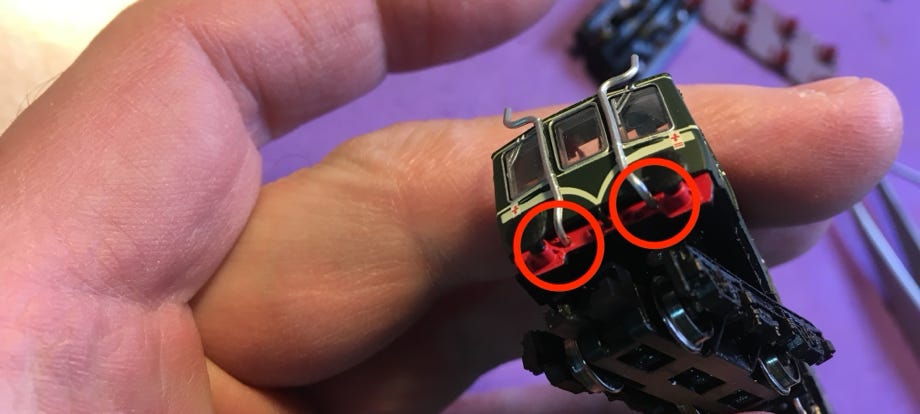

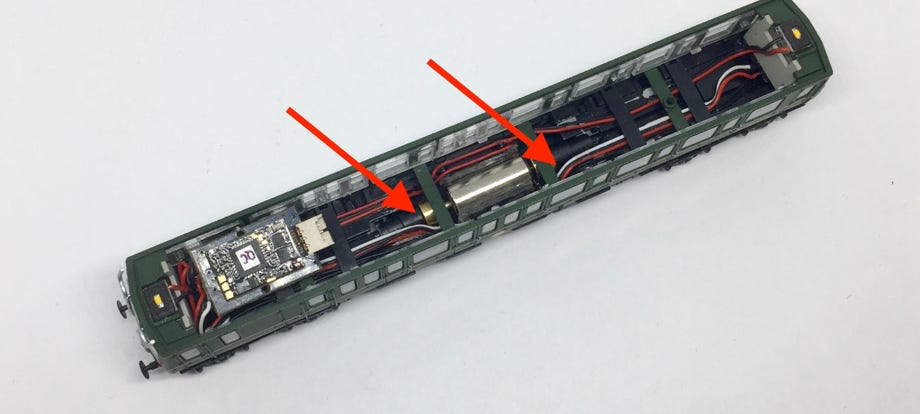

Conversion Dapol Class 121/122

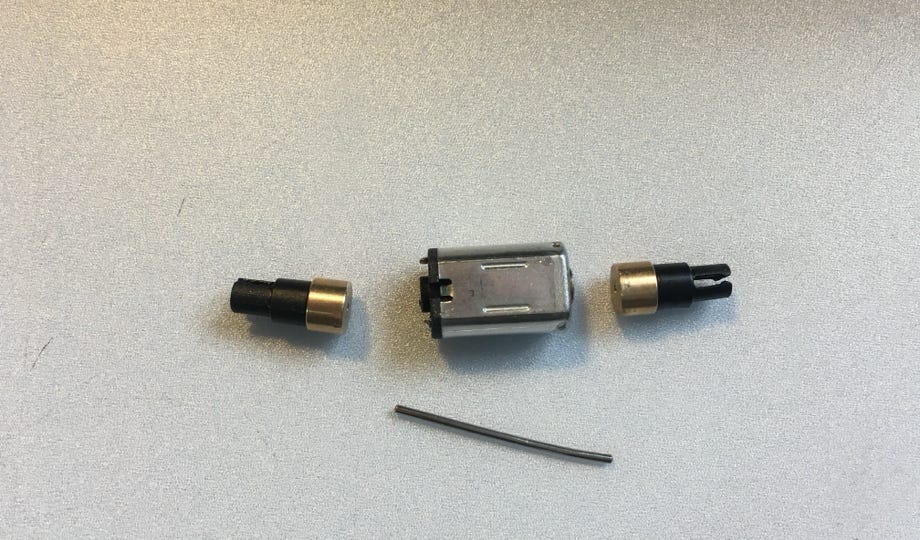

to coreless motor

What you need for conversion set

- Dapol Class 121 or 122 N gauge

- Small flat screwdriver

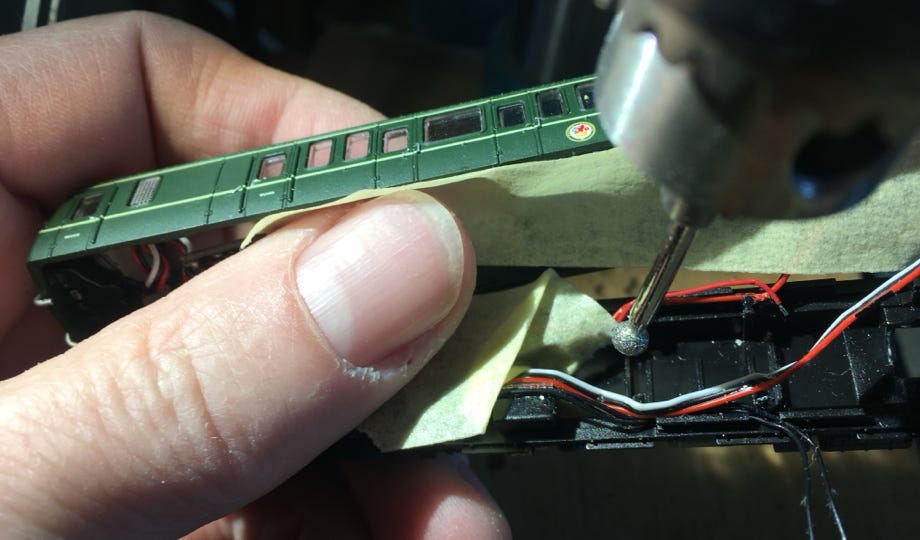

- Soldering iron 15W/25W

- Thin wire (link)

- Rotary tool (Dremel etc)/Pilar drill

Makes the work easier:

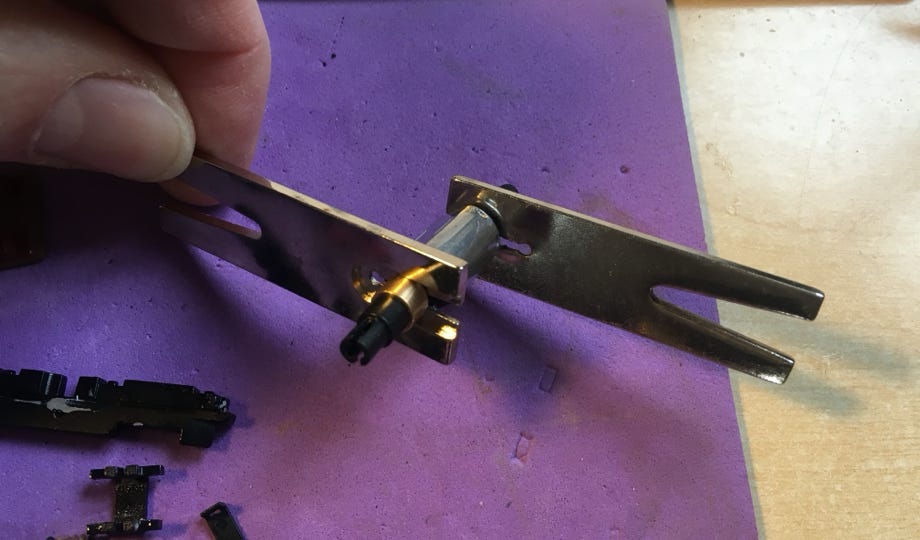

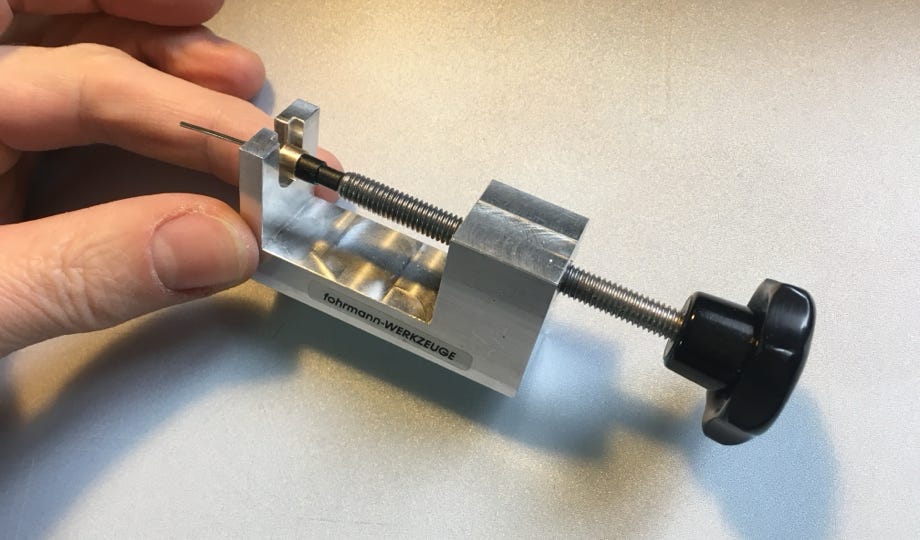

- Gear puller (link)

- Reamer 0.99 mm

Installation time: <2 hours

Gear fitting service available: You send original motor to us, we take it apart and install flywheels on new motor.

Question? Just reach out!