UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

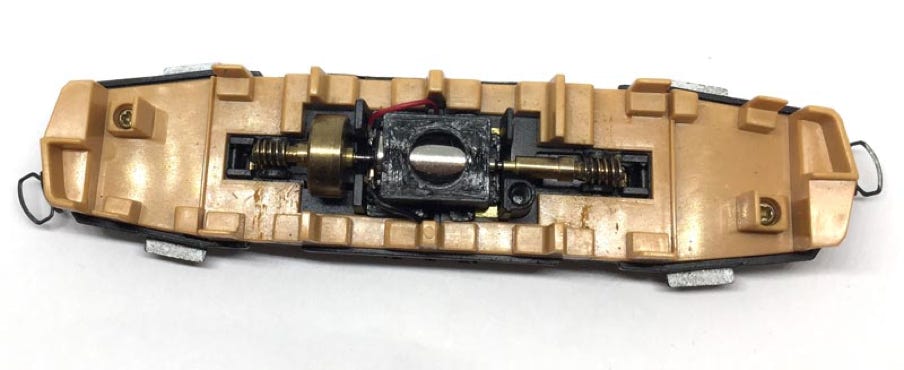

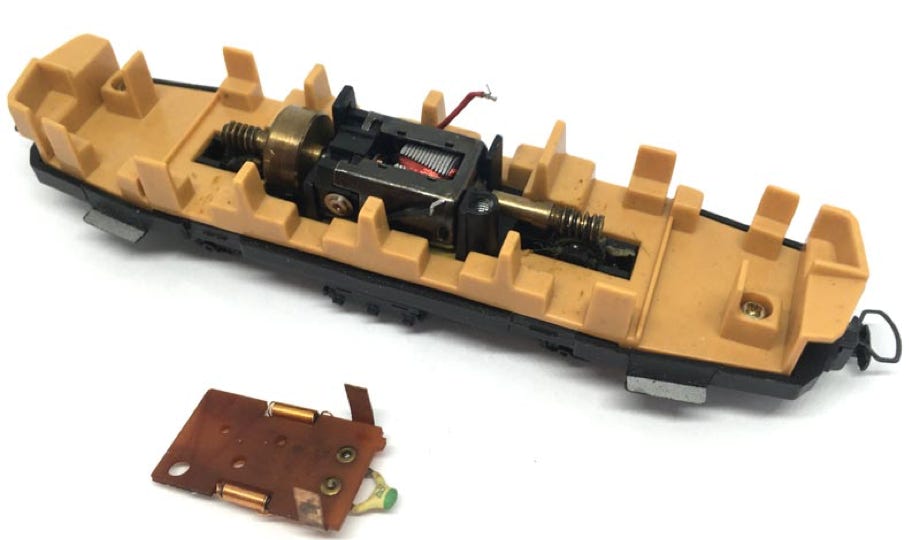

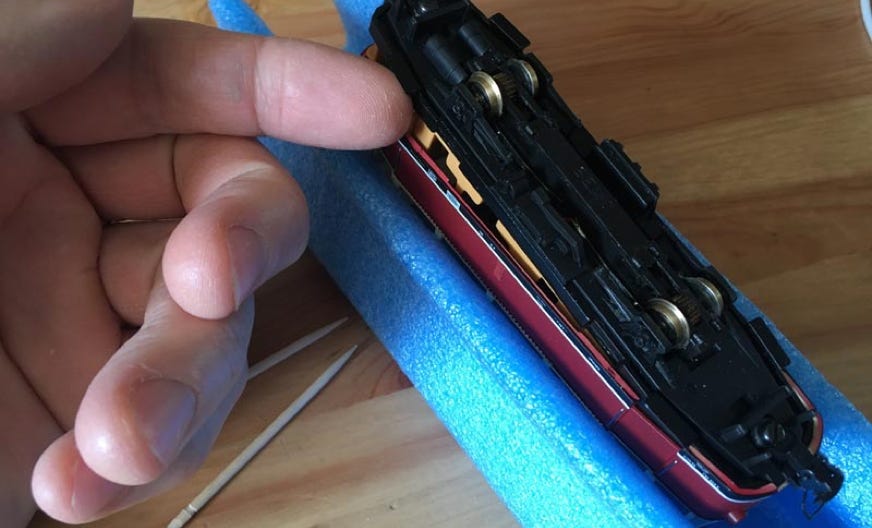

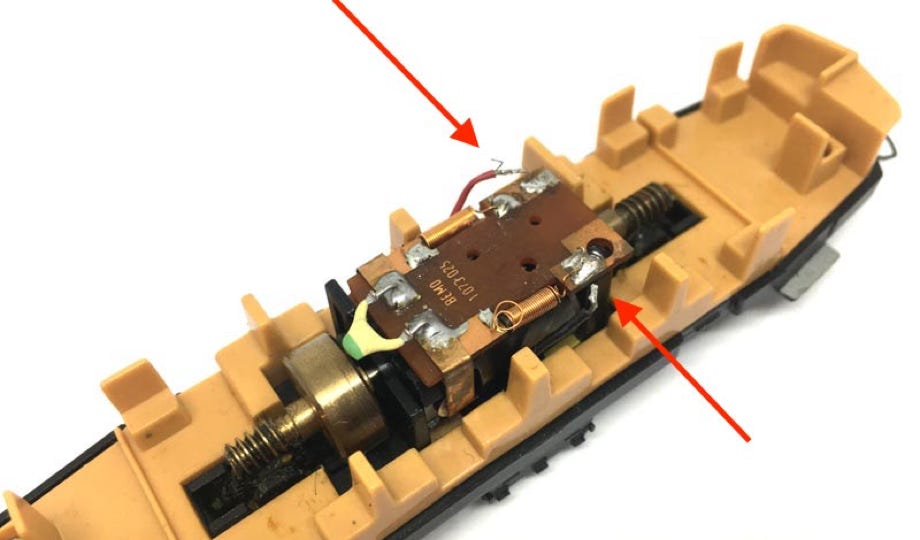

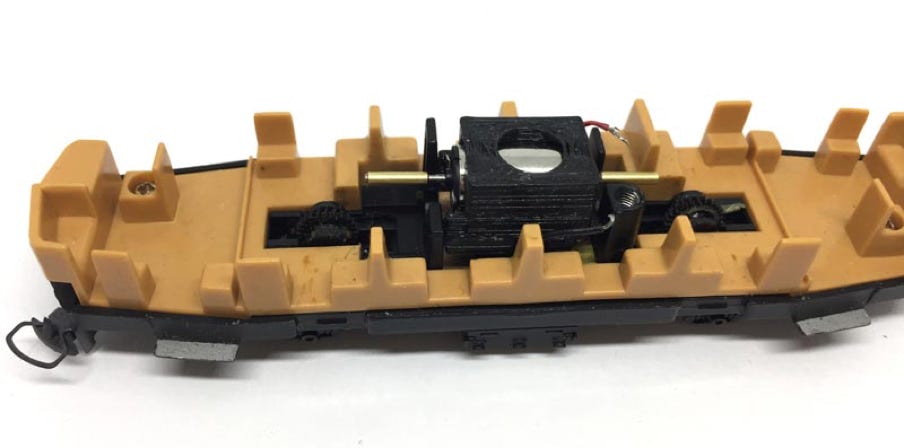

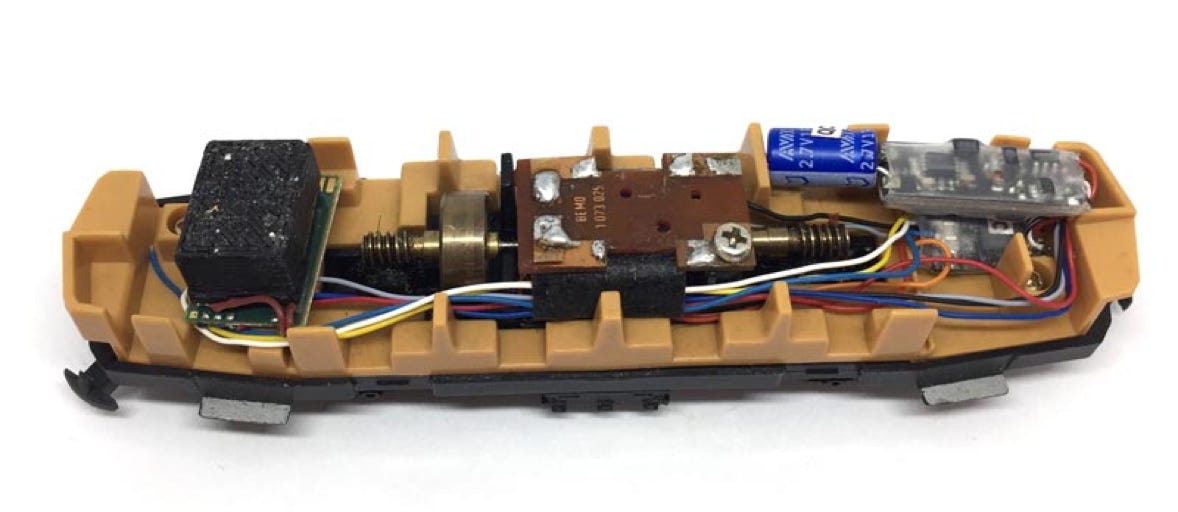

Conversion Bemo Fliegender Spreewalder

to 12V coreless motor

Fits Bemo Art 1233 833, 1233 813 H0e/H0m.

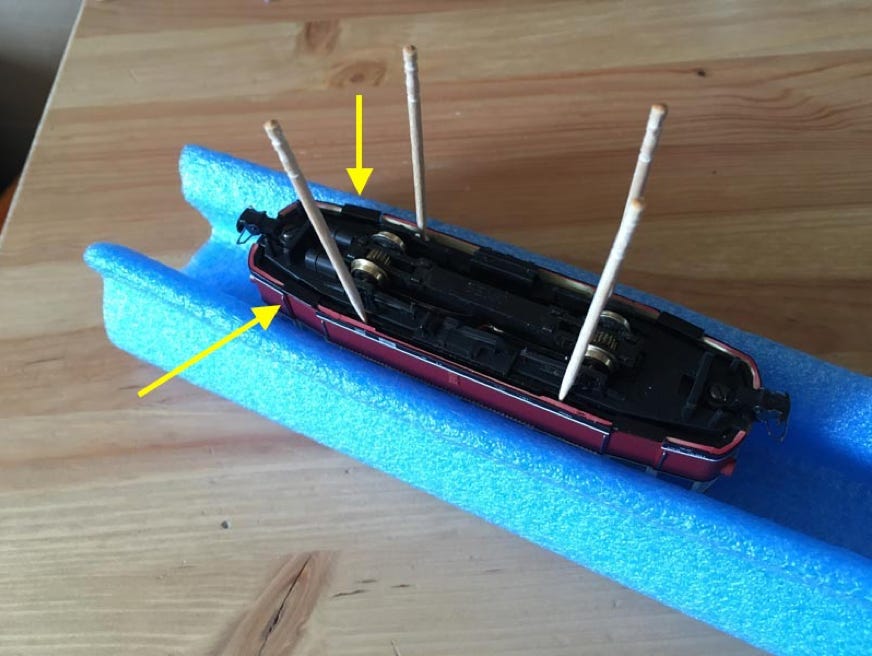

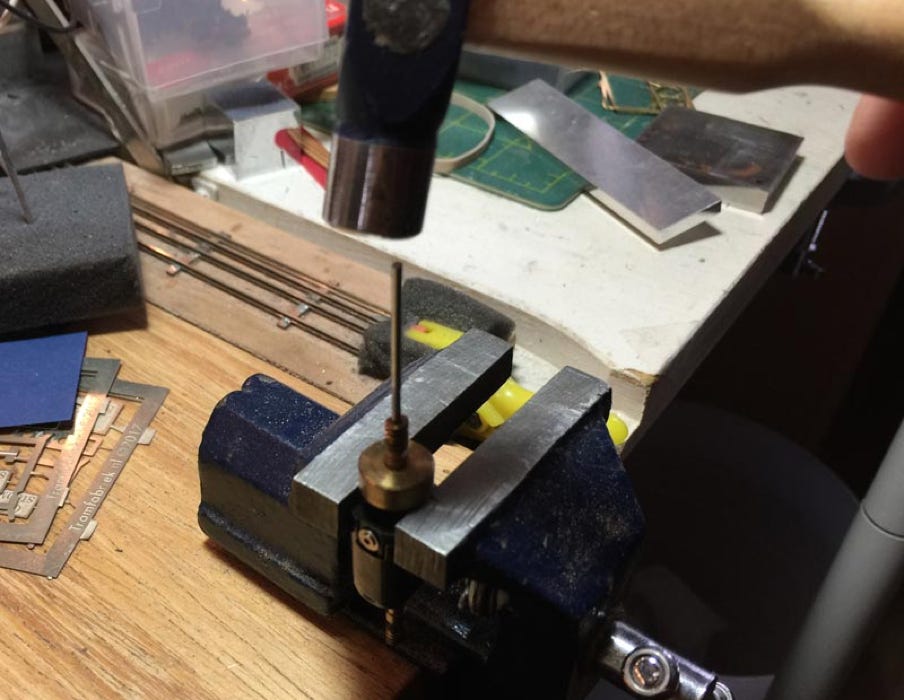

What you need for conversion set

- The model and upgrade kit

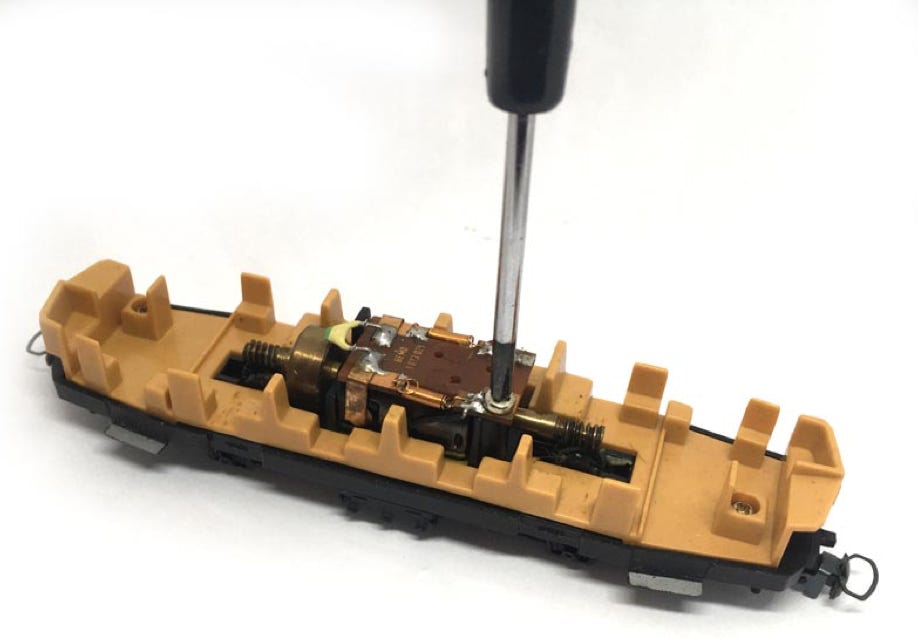

- Small flat screwdriver

- Soldering iron 15W/25W

- Thin wire (get the thinnest wire here)

Good to have:

- General modelling tools

Installation time: Around 45 minutes

Art. code: BESPREE

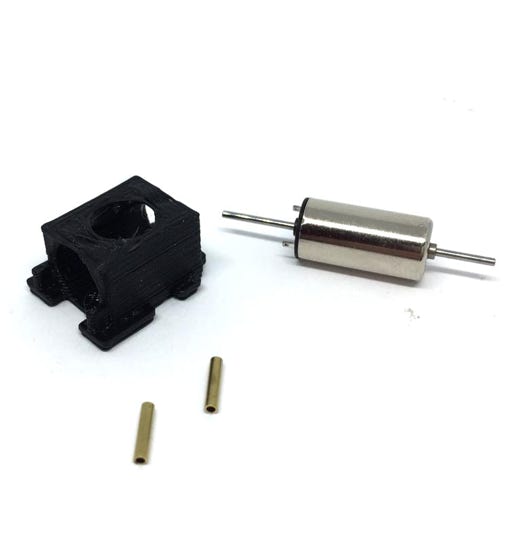

Contents of the kit

1x 8x16 mm motor double shaft

1x motor casing

2x brass adapters