UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

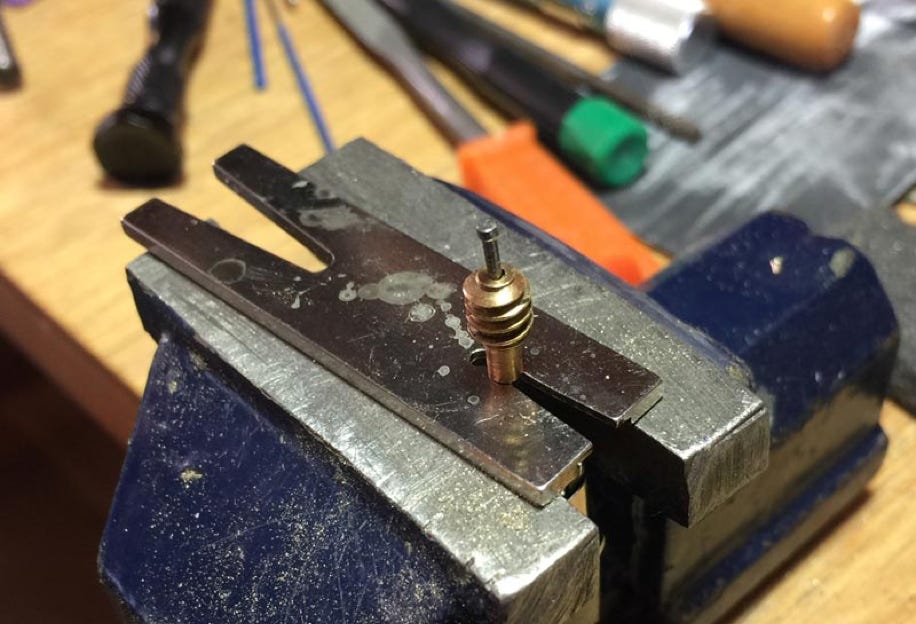

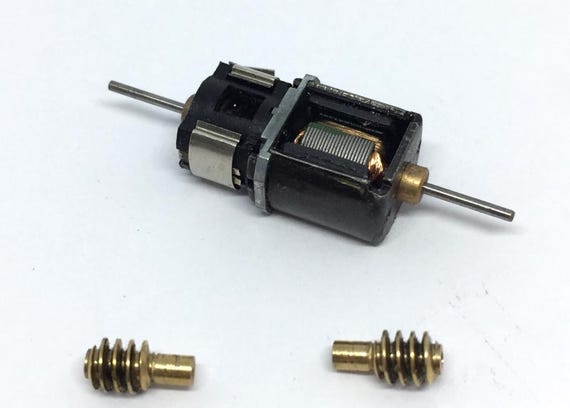

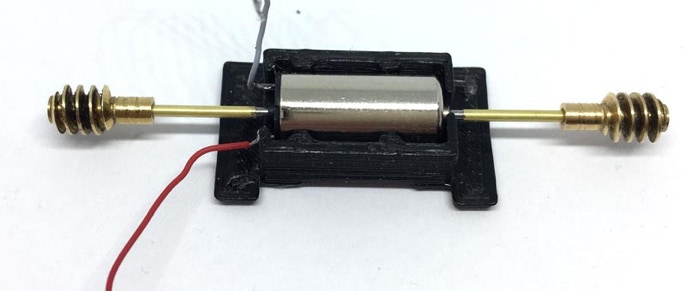

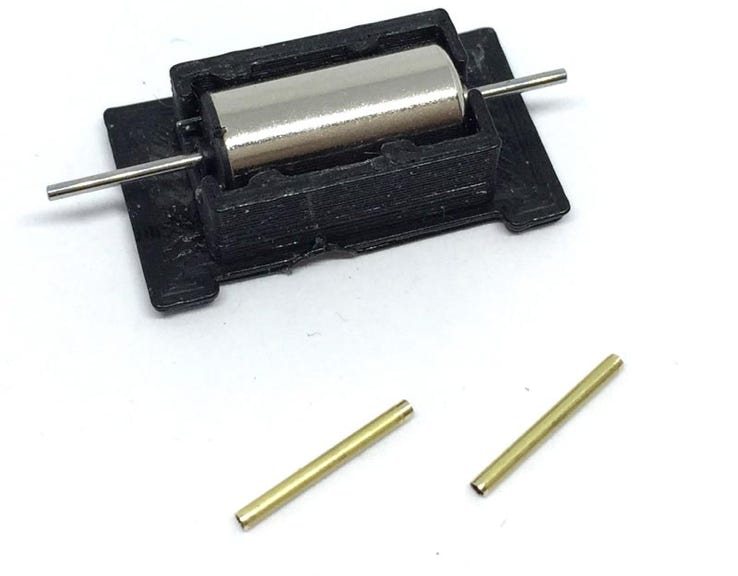

Conversion Minitrix V160 ‘Lolo’

to 12V coreless motor

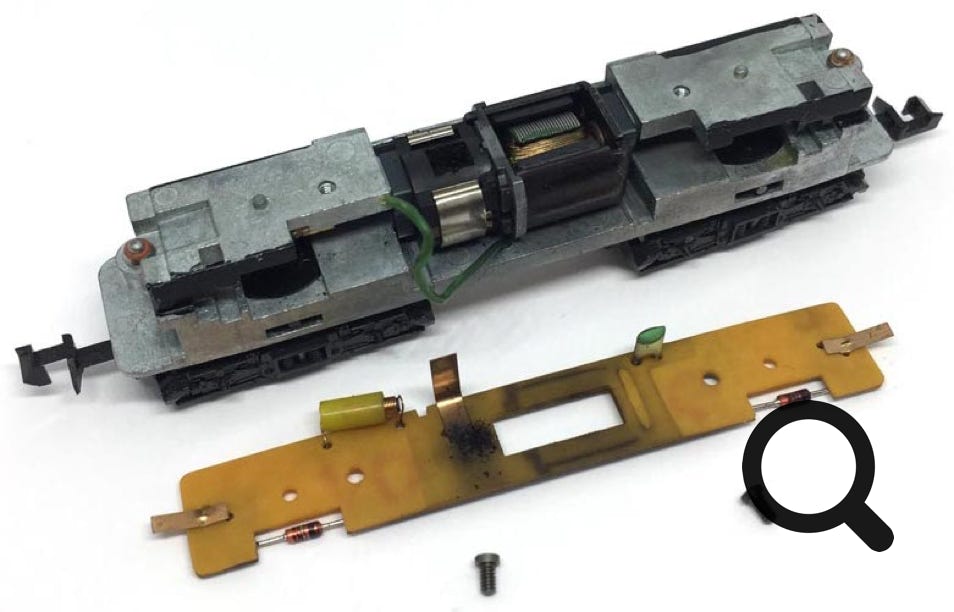

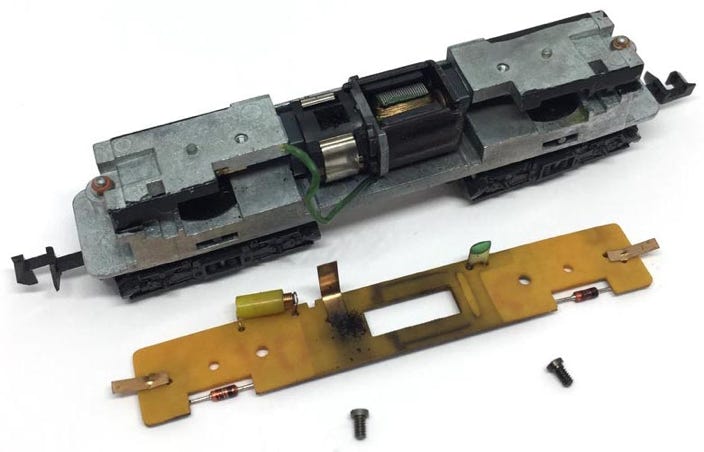

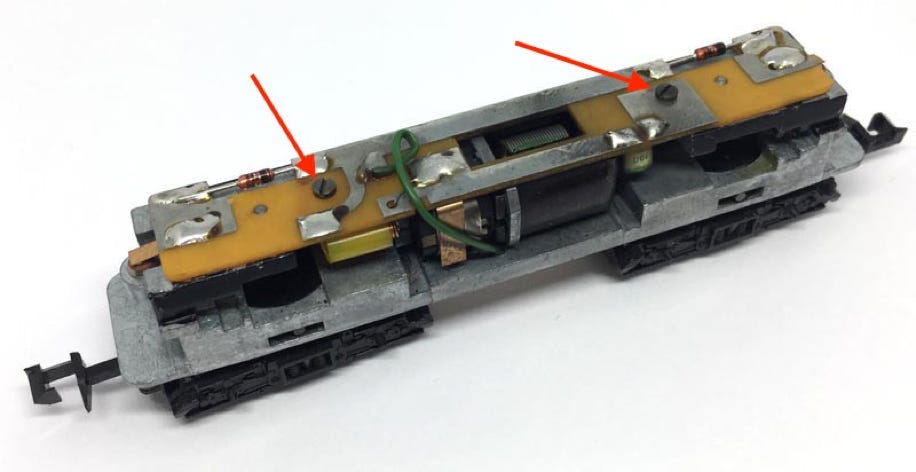

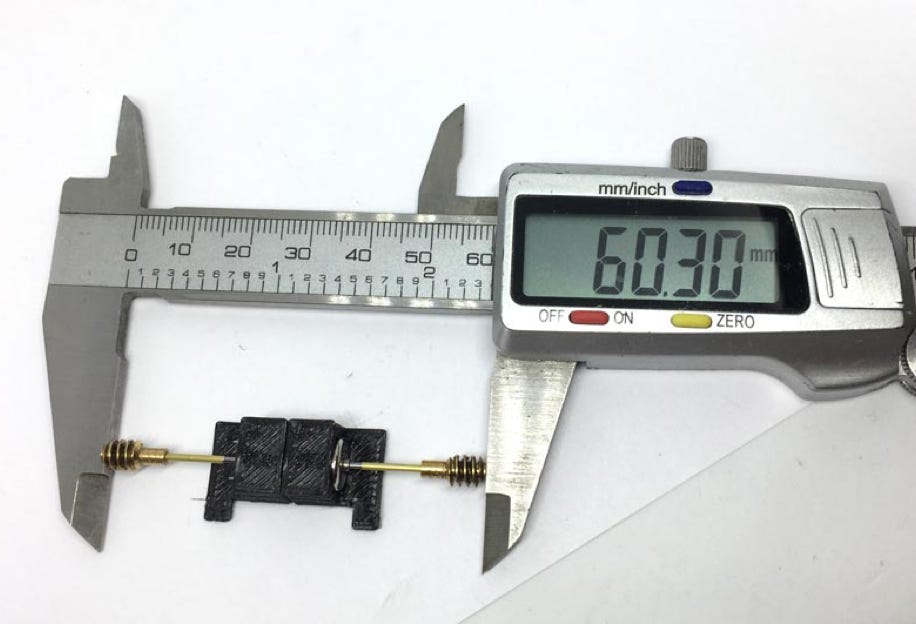

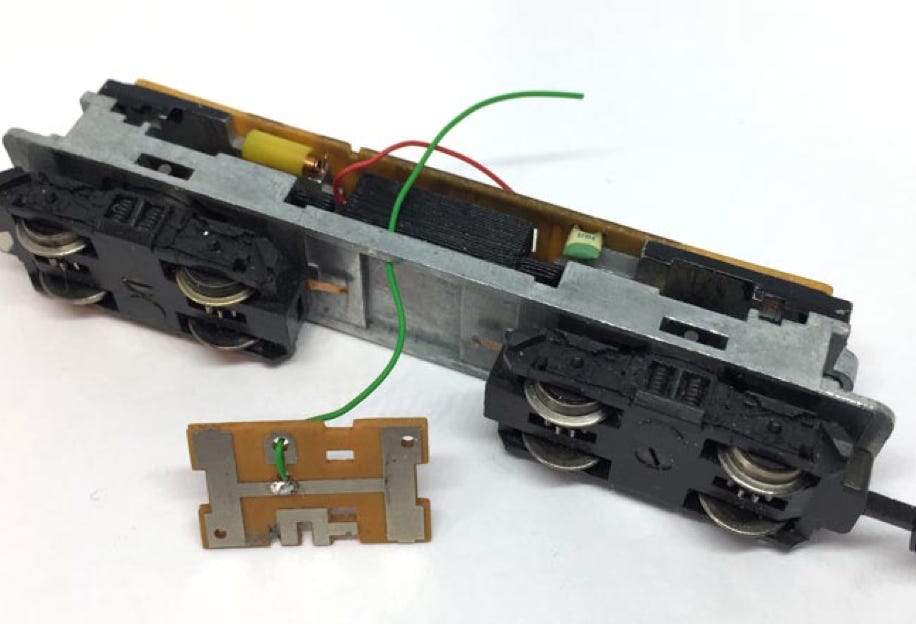

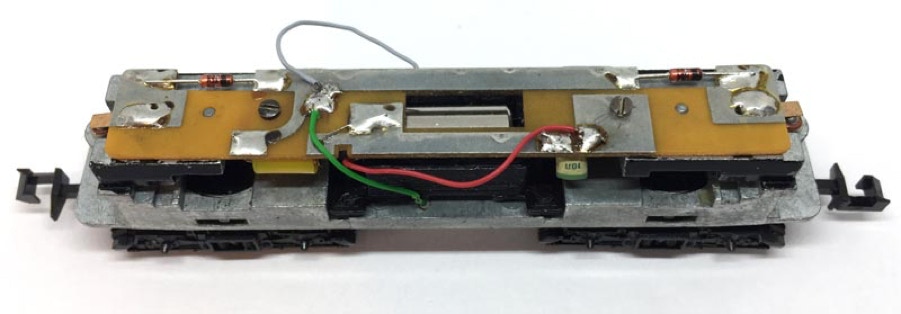

Fits all Minitrix art. 11107, 11108, 12423, 12460, 12461, 12501, 12846, 12874. Will even be suitable to similar designed Minitrix locomotives (compare inside of your model with the pictures).

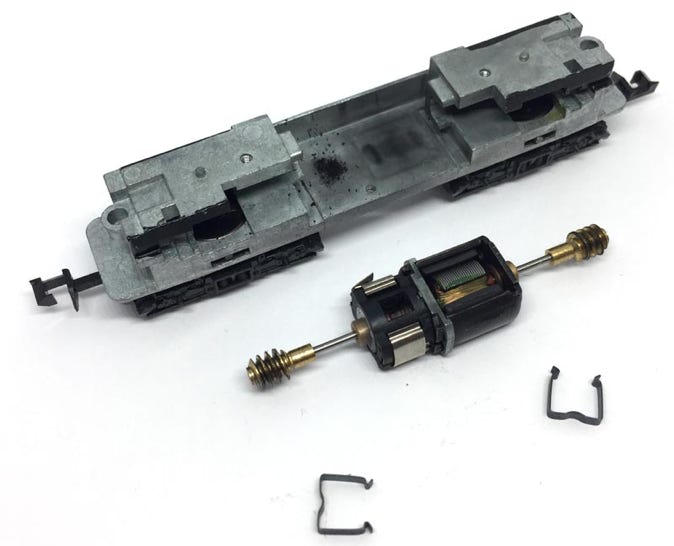

Original frame. Compare your model to see if it is similar.

Question? Just reach out!