UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

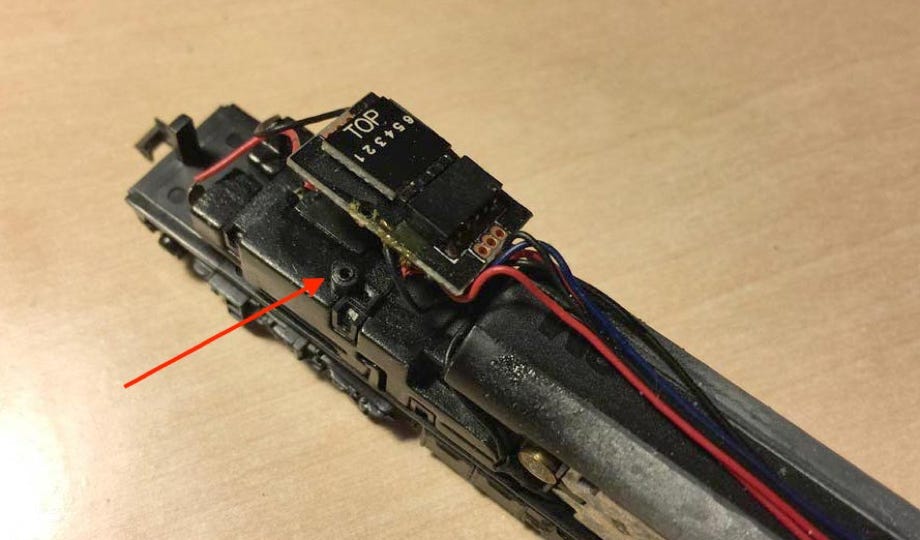

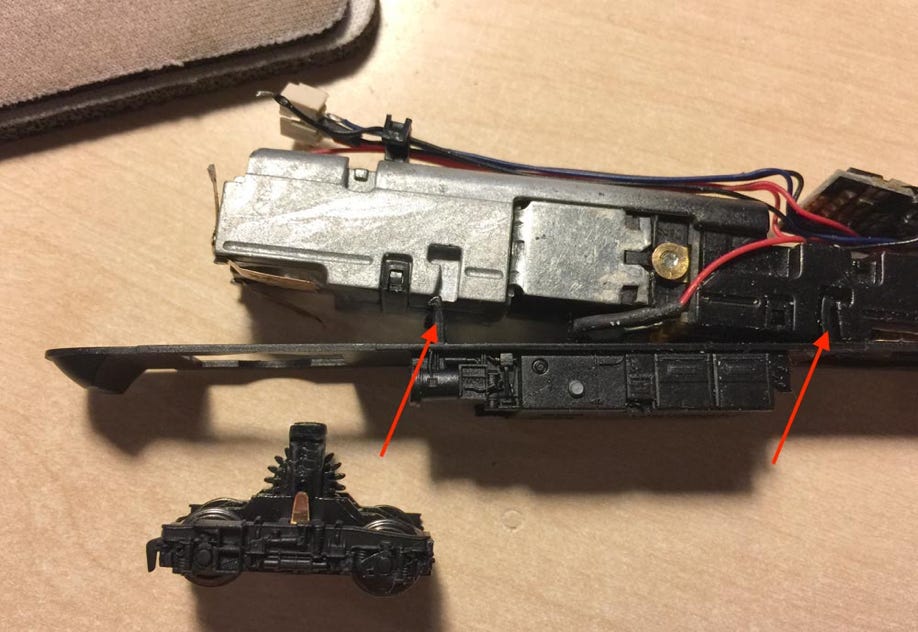

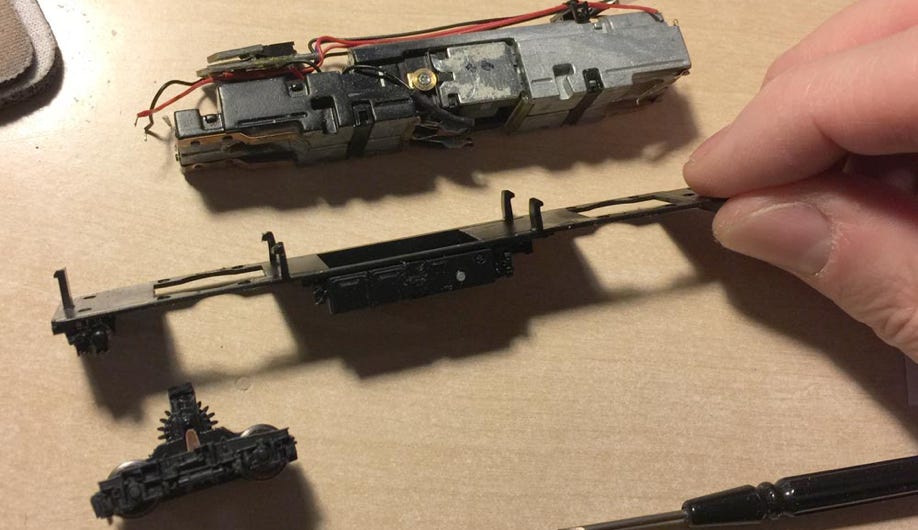

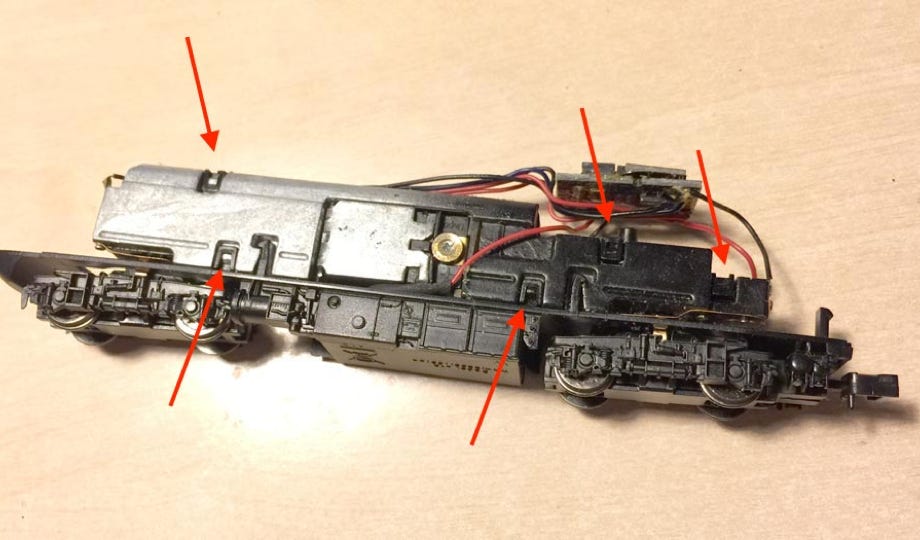

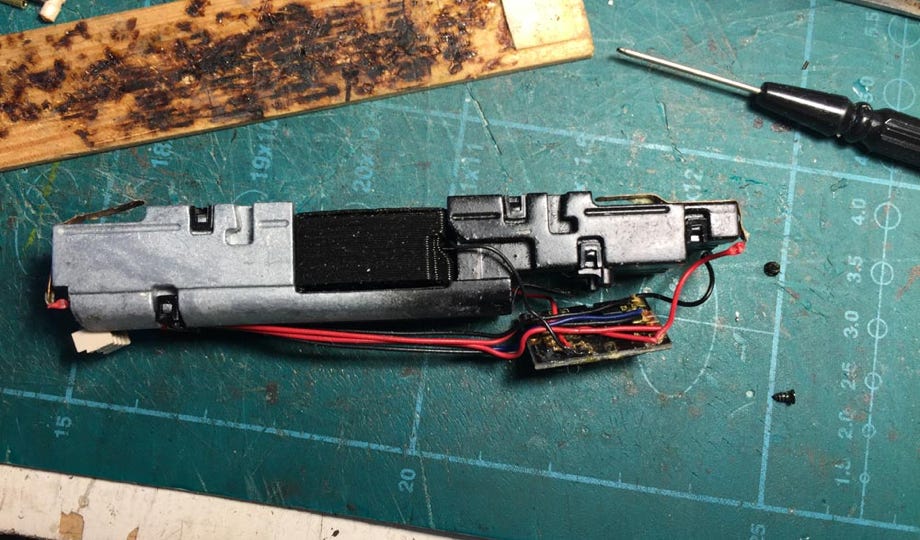

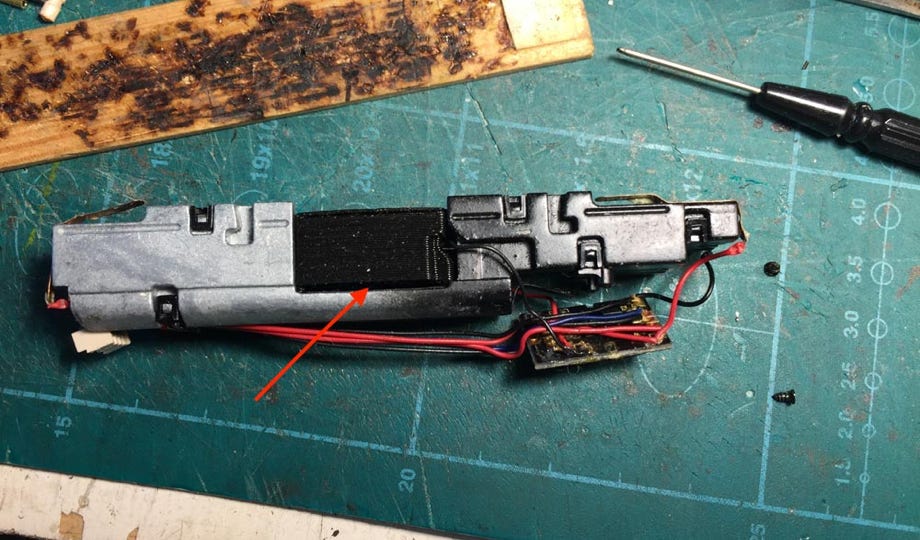

Conversion Dapol Class 43

to 12V coreless motor

Fits all Dapol class 43 models.

What you need for conversion set

- The model and upgrade kit

- Small flat screwdriver

- Soldering iron 15W/25W

- Thin wire (get the best wire here)

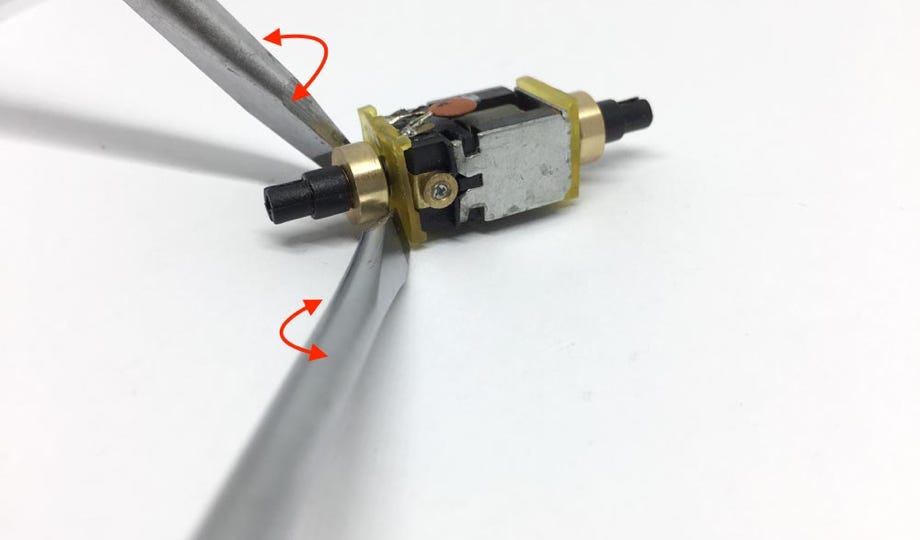

- 2 screw drivers with a large head

Good to have:

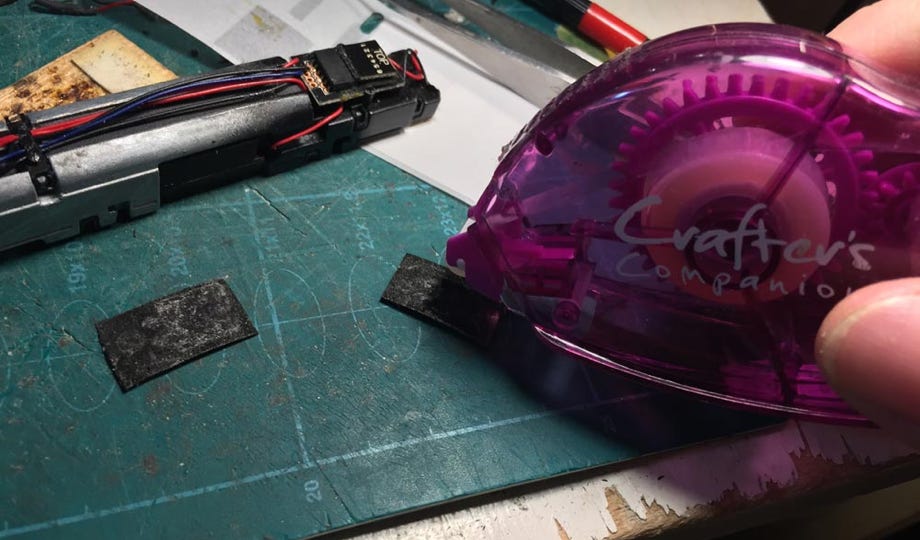

- Double sided tape (medium thick)ness

Installation time: Around 1 hour

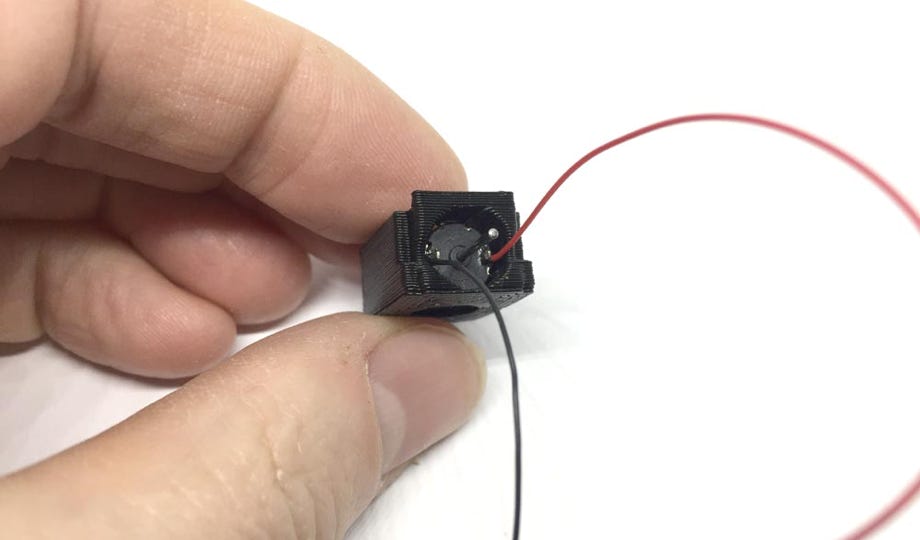

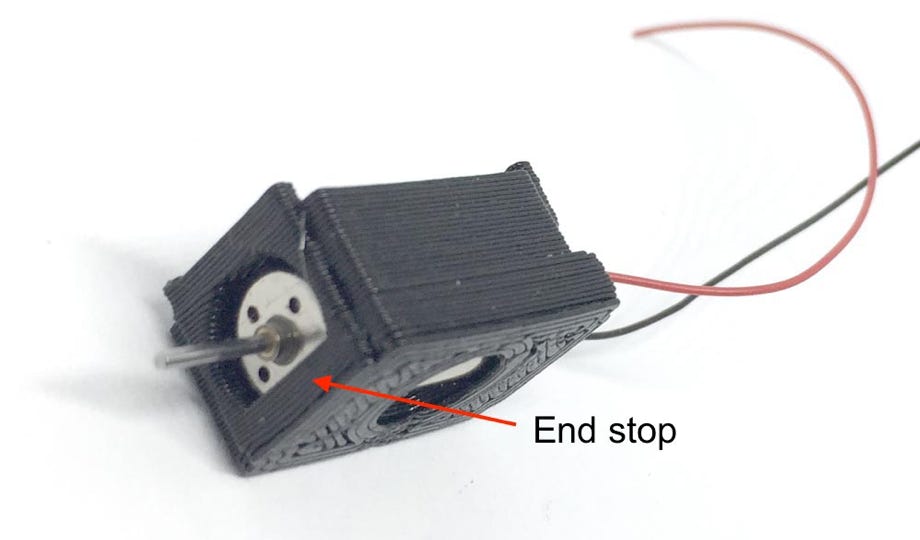

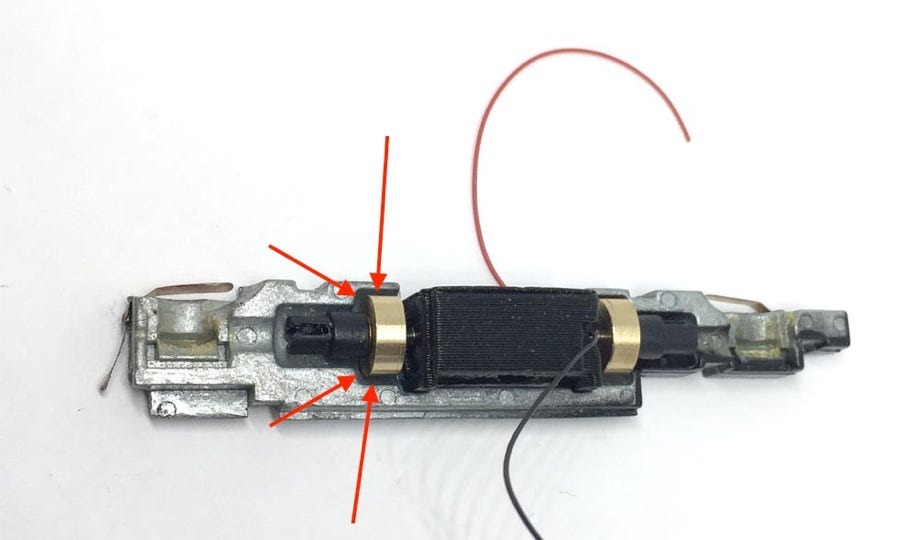

Contents of the kit. Size of brass adapters can differ in your kit.