UK based

Prices for UK customers are shown inc 20% VAT

Other countries, inc EU, prices shown are ex VAT.

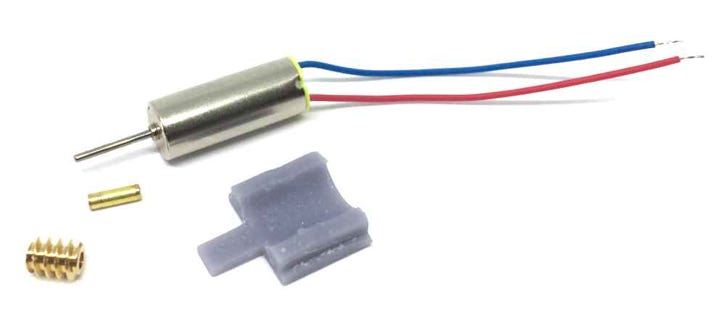

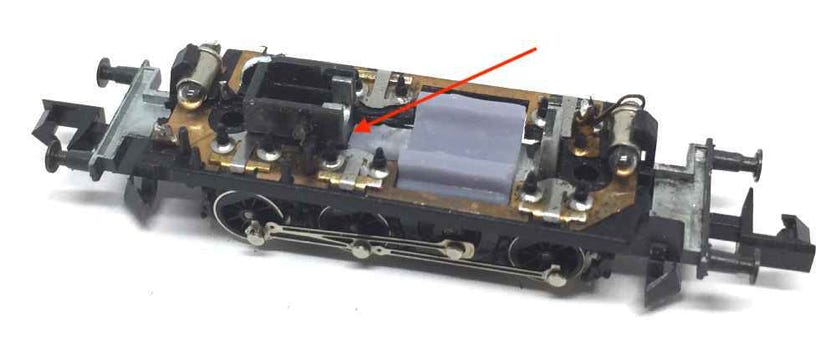

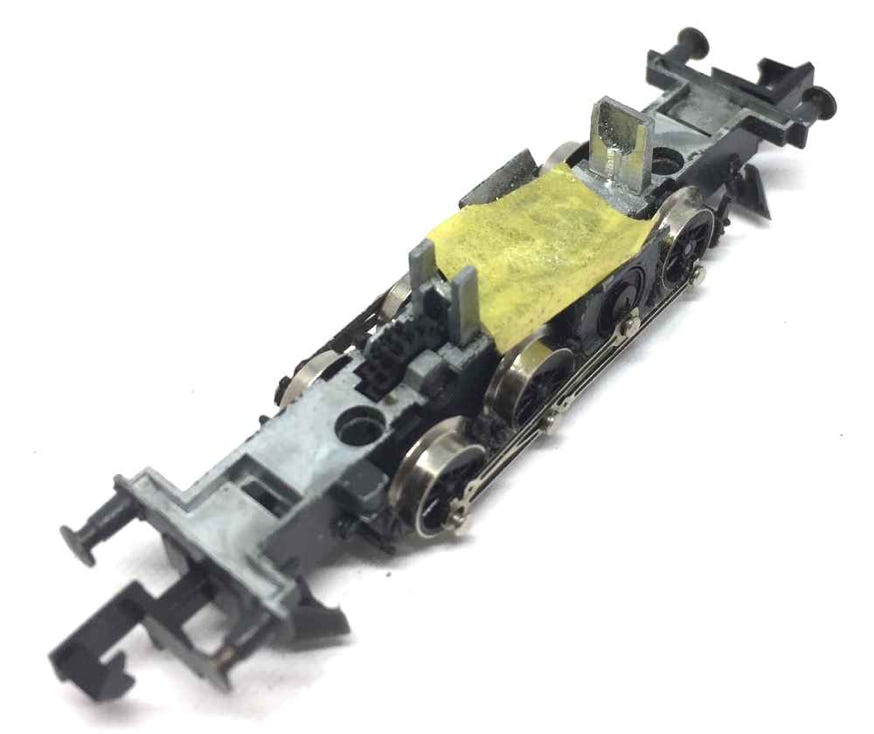

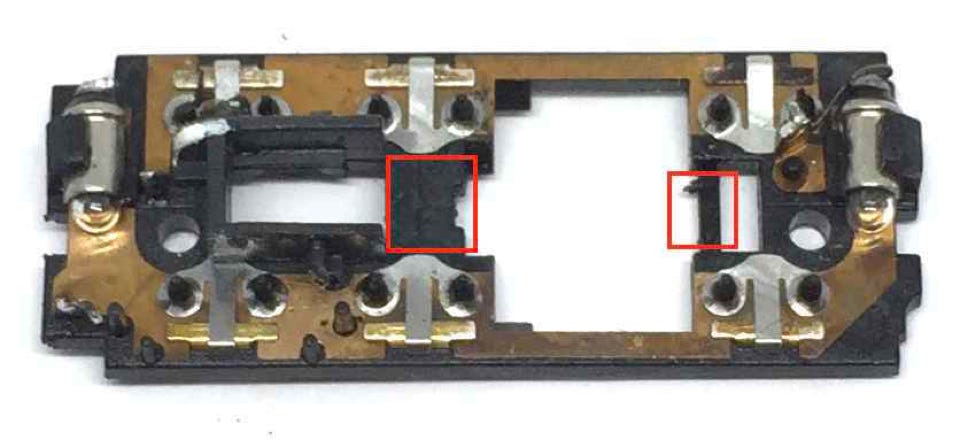

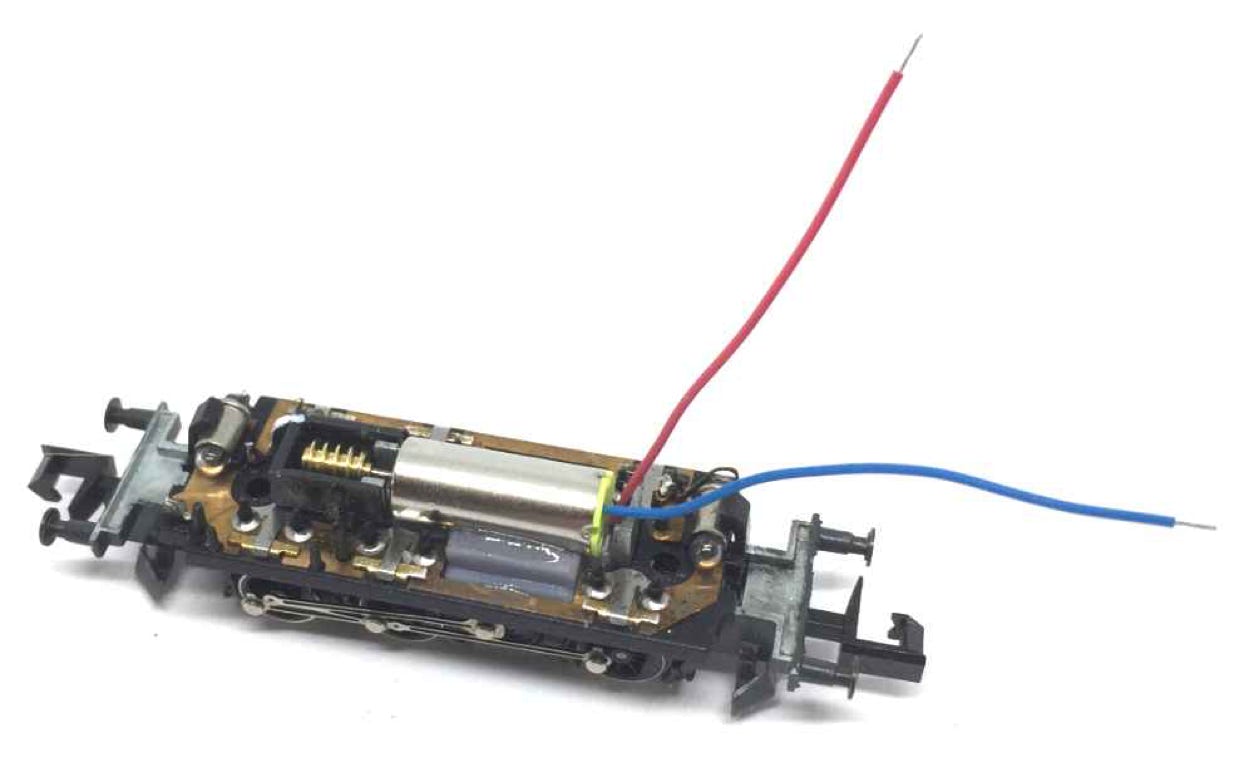

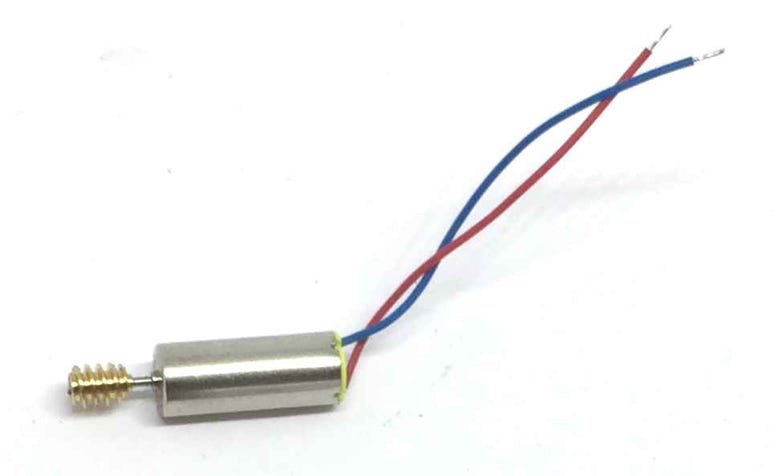

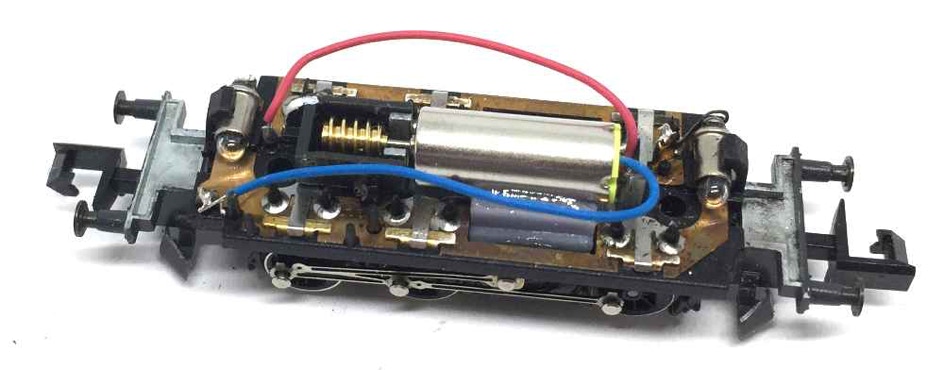

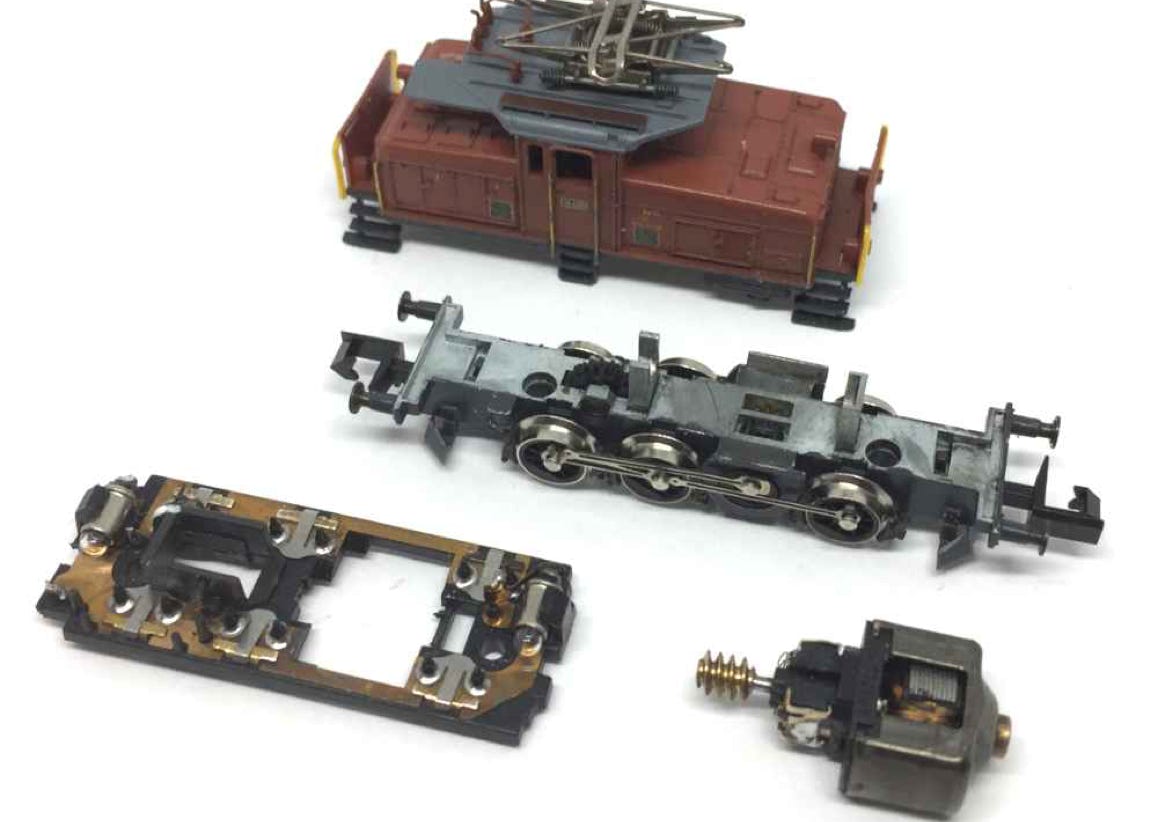

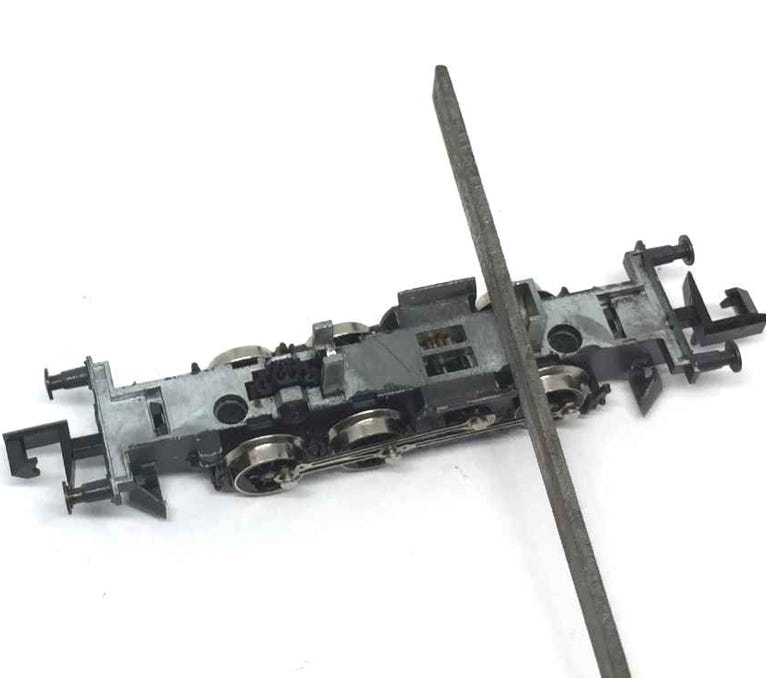

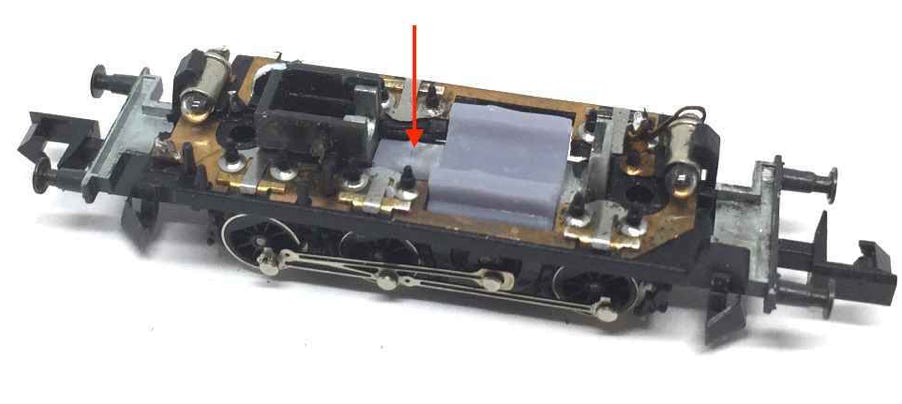

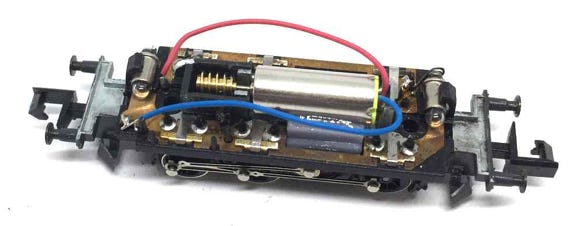

Upgrade Arnold Ee 3/3

to 12V coreless motor

Fits Arnold art. 0104, 0109, 0160, 0161, 0215, 2420, 2421, 2422, 2423, 2424, 2425, 2426, 2427, 2428, 2431, 8620 and similar models (open your model to check compatibility).

Question? Just reach out!